In the world of finishing techniques, powder coating dip stands out for its durability and versatility. Industry expert John Smith, a seasoned professional in coatings technology, emphasizes this point when he says, “Powder coating dip can transform surfaces, offering protection and aesthetic appeal.” This technique has gained popularity among manufacturers seeking reliable solutions.

Using powder coating dip requires precision and understanding. It involves dipping the item into a specially formulated powder mixture. The process not only enhances the visual appeal but also ensures long-lasting protection against the elements. Proper application can lead to a flawless finish, yet achieving that perfection can be challenging. Factors like temperature and consistency play a crucial role in the outcome.

There are common pitfalls to be aware of. Improper preparation can result in uneven surfaces or poor adhesion. Additionally, achieving the right color match may take several attempts. Thus, while powder coating dip offers impressive benefits, it requires careful consideration and practice. Embracing these challenges can lead to a refined skillset and significantly improved results.

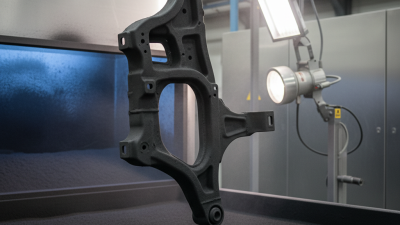

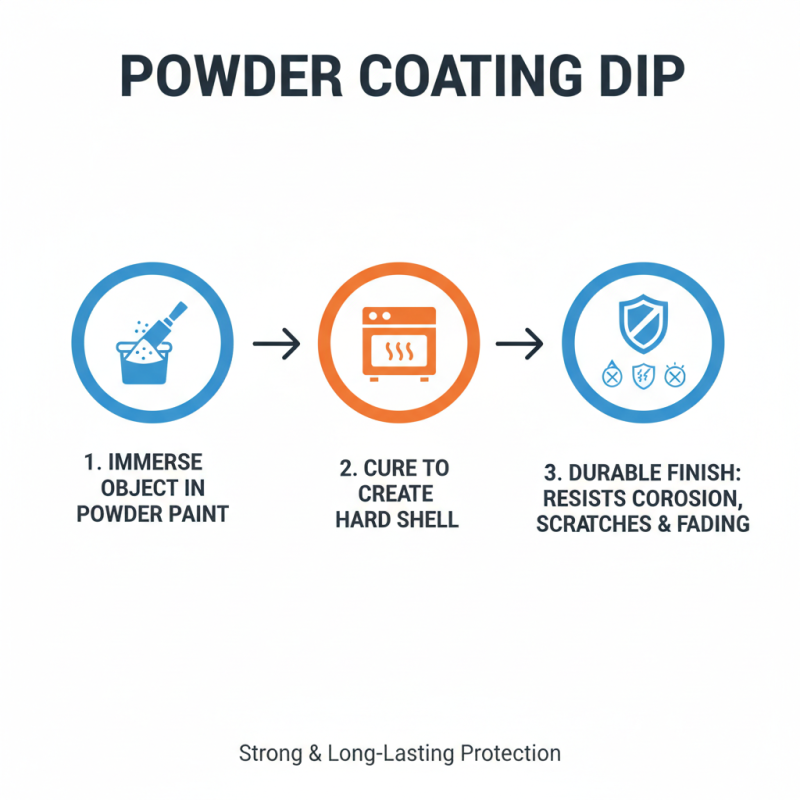

Powder coating dip is a unique technique for applying durable finishes. It involves immersing an object in a powder paint and then curing it to create a hard shell. This process leads to strong resistance against corrosion, scratches, and fading.

One key benefit of powder coating dip is its versatility. Various materials can be coated, such as metals and plastics. The finish is customizable, offering a range of colors and textures. The final look can be smooth, textured, or even metallic.

Tips: Always clean the surface before dipping. Any dirt or grease can ruin the finish. Also, maintain a consistent temperature in your curing oven. Too hot or too cold can affect adhesion. Lastly, consider starting with small projects. This helps you understand the process without overwhelming mistakes. Each project offers a learning opportunity. Reflect on what works and what doesn’t.

To achieve a durable finish using powder coating dip, specific tools and materials are essential. You need a clean workspace. Dust and debris can ruin your final result. Gather the necessary safety gear, including gloves and masks. Safety is paramount during this process.

A powder coating gun is crucial for applying the powder evenly. You'll also need a dip tank, often filled with a specific type of powder. Make sure to choose high-quality powder. It should be compatible with your projects. A heat source is necessary to cure the coating properly. An oven works well for smaller items.

Don’t forget to have cleaning supplies on hand. Properly prepping your items is vital. Sometimes, imperfections may appear. Look for blemishes after coating. Adjusting your application technique can help. Mistakes can lead to waste, so practice is essential. This process takes time and patience. Your final finish depends on it.

Preparing items for powder coating dip requires careful attention to detail. Start by selecting items that are clean and free of any contaminants. Remove dirt and grease using a degreasing solution. This is crucial, as any residue can affect the finish. After cleaning, inspect the surface for rust or damage. If you find any, treat it before proceeding.

Next, consider the surface type. A rough surface can improve adhesion but may require sanding. Use sandpaper or a blasting technique to create the desired texture. Ensure that edges and corners are smooth. Any imperfections can lead to uneven coating, which may be disappointing later on. After preparing the surface, rinse it thoroughly to eliminate any sanding dust.

Once cleaned and dried, hang items using hooks or a wire system. This allows the powder coating to reach all areas evenly. Avoid touching the surface after cleaning. Oils from your fingers can lead to flaws in the finish. Remember, preparation is key, and skipping these steps might lead to out-of-control issues down the line.

This bar chart demonstrates the estimated time required for each step in the powder coating process, including Surface Preparation, Powder Application, Curing Process, Cooling Down, and Final Inspection. Proper preparation of items ensures a durable and high-quality finish.

Applying powder coating dip can yield impressive, durable finishes when done correctly. The technique involves submerging an item in a fluid powder coating and allowing it to adhere and cure. This method is popular for its efficiency and effectiveness. According to industry reports, properly applied powder coating can be up to three times thicker than liquid paint, providing superior protection against corrosion and wear.

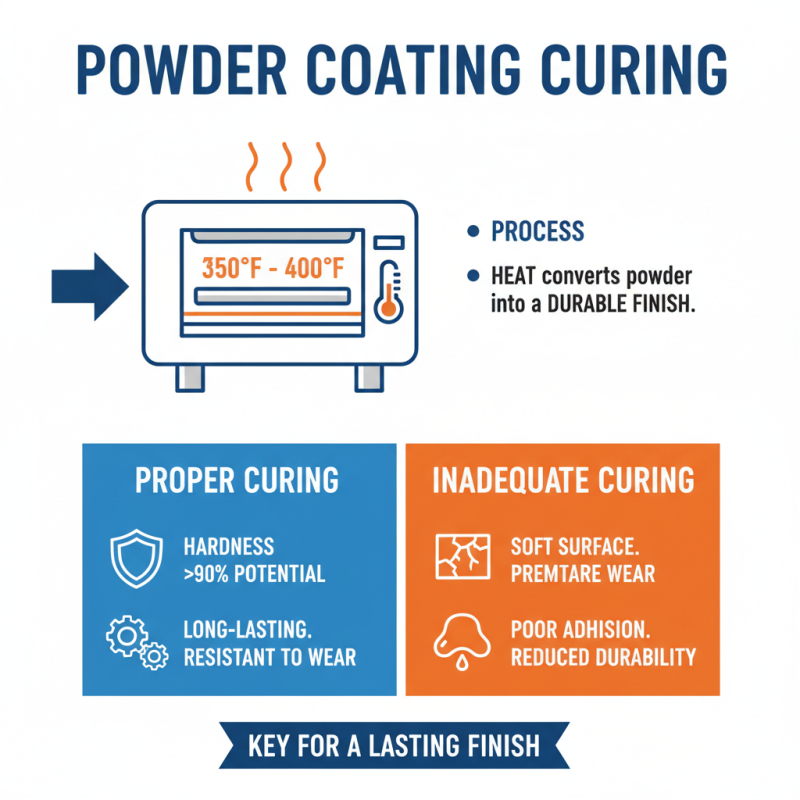

Achieving the desired finish requires attention to detail. Surface preparation is critical. Items should be cleaned and free from rust or dust. Any flaws can affect the final layer of coating. Once submerged, maintain a consistent dipping speed. A sudden or erratic motion can lead to uneven finishes. The ideal curing temperature varies by formula, often needing between 350°F to 400°F. Use a thermometer to ensure the correct heat range for optimal results.

**Tips:** Ensure the workspace is free from contaminants. Wear appropriate protective gear during the process. Regularly calibrate your equipment to avoid uneven thickness. Review your process frequently. Mistakes can lead to wasted materials and time. Reflecting on your methods is essential for improvement. Experiment with different settings to find what works best for your specific applications.

| Technique | Description | Tips | Best For |

|---|---|---|---|

| Pre-Treatment | Cleaning and preparing the surface to remove any contaminants. | Use a degreaser and ensure the surface is completely dry. | Metal surfaces, particularly steel and aluminum. |

| Dipping Technique | Immersing the object in a powder coating dip solution. | Ensure even coverage by dipping straight and slowly. | Small parts and intricate designs. |

| Curing Process | Heating the coated object to polymerize the powder. | Follow the manufacturer's recommended temperature and time. | Durable finishes on automotive parts, furniture, and outdoor equipment. |

| Post-Curing Treatment | Final inspections and potential touch-ups or refinishing. | Inspect for any defects and sand down rough edges. | Products requiring high durability or aesthetic finishes. |

Curing is a critical process in powder coating. It transforms the applied powder into a durable finish. Typically, this involves heating the coated object in an oven. The ideal curing temperature often ranges from 350°F to 400°F. Properly cured surfaces can achieve more than 90% of their potential hardness. Inadequate curing leads to soft surfaces and premature wear.

Finishing touches can significantly enhance the appearance and longevity of powder-coated products. One effective approach is the application of a clear coat. This adds another protective layer, improving UV resistance and preventing oxidation. Reports suggest that a clear coat can enhance gloss levels by up to 50%. However, applying additional layers can sometimes trap moisture. It's important to manage thickness to avoid issues like bubbling.

Despite advances, achieving a flawless coating remains a challenge. Surface imperfections can emerge from dust or improper application techniques. Experts recommend thorough surface preparation to minimize these risks. Regular quality checks during the process can help identify problems early. Staying aware of these factors helps in creating powder-coated surfaces that are not just visually appealing but also durable and long-lasting.