In the fast-evolving field of industrial coatings, plastisol dip coating has gained immense popularity. This method is lauded for its durability and protective qualities. According to a report by the Industry Research Group, the global plastisol market is projected to grow at a compound annual growth rate of 5.6% from 2023 to 2028. Such figures highlight the importance of efficient application techniques.

John Smith, a leading expert in coating technologies, once stated, "Plastisol dip coating not only offers a protective barrier but enhances product aesthetics." This underscores the dual functionality of plastisol dip coating in industrial applications. However, achieving effective protection requires attention to detail and precise execution.

Many manufacturers struggle with consistency in coating thickness and adhesion. Recognizing the specific requirements of different substrates is essential yet often overlooked. Moreover, the disposal of excess plastisol waste poses environmental concerns that the industry must address. Effective training and awareness can help improve practices, ensuring better outcomes and environmental responsibility.

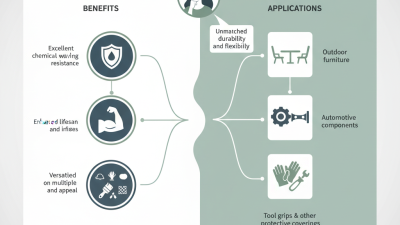

Plastisol dip coating is a popular method for protecting various surfaces. It involves dipping an item into a heated plastisol solution. This forms a tough, durable layer that adheres well to the substrate. The resulting coating can resist scratches, corrosion, and chemicals.

The process begins by cleaning the surface thoroughly. Any contaminants can affect adhesion. Once dipped and cured, the coating typically ranges from 0.020 to 0.125 inches in thickness. According to industry reports, this method provides up to five times more abrasion resistance than traditional paint. However, the precision of control during the application can be challenging.

To achieve optimal results, the temperature and dwelling time during the dip should be monitored closely. A small miscalculation can lead to uneven coverage or weak spots. Additionally, while plastisol is effective, it does have its limitations in high-temperature environments. Despite these potential drawbacks, the cost-effectiveness and ease of use make plastisol dip coating an appealing option for many industries.

Plastisol dip coating is an excellent choice for protection in various applications. It creates a thick, rubbery layer that adheres well to surfaces. This coating effectively resists scratches, corrosion, and impacts. The soft finish provides a comfortable grip, which is essential for tools and handles. You don't have to worry much about wear and tear when using this coating.

Another significant benefit is the ease of application. It can be dipped, brushed, or sprayed. The method allows for versatile use across different materials. However, coatings can sometimes be inconsistent in thickness. Some users may notice bubbles or uneven areas, prompting a need for careful inspection after application. It’s crucial to follow the instructions closely to avoid these issues.

The coating is also customizable. Different colors and finishes can be achieved, enhancing aesthetic appeal. However, color choices may fade over time. Users need to be aware of this to maintain their products' appearance. Proper care extends the life of plastisol coatings and ensures they provide reliable protection. Even with minor imperfections, the benefits of plastisol dip coating outweigh the downsides.

| Dimension | Description | Benefits |

|---|---|---|

| Durability | Provides a strong, resilient coating that withstands abrasion and impact. | Increases product lifespan and reduces replacement costs. |

| Corrosion Resistance | Protects metal surfaces from oxidation and rust. | Improves outdoor performance and longevity of products. |

| Chemical Resistance | Withstands exposure to various chemicals and solvents without degrading. | Ensures product reliability in harsh environments. |

| Non-Slip Surface | Creates a textured surface that enhances grip. | Increases safety for users handling coated items. |

| Aesthetic Appeal | Available in various colors and finishes. | Enhances product appearance for branding and design purposes. |

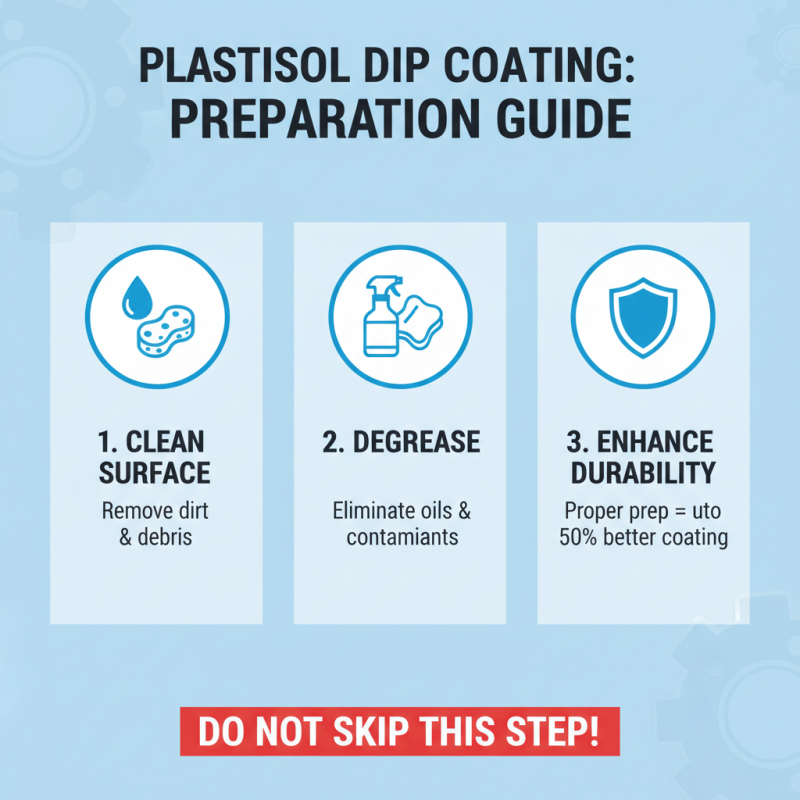

Plastisol dip coating is an effective way to protect various surfaces. The application process is crucial. Proper preparation can enhance durability. Start by cleaning the surface thoroughly. Use a degreaser to remove oils and contaminants. This step is vital. Reports suggest that improper cleaning can reduce coating effectiveness by up to 50%.

Next, preheat the coated item. The temperature should be around 350°F (175°C). This helps the plastisol adhere better. Immersing the item in the plastisol solution follows. Ensure even coverage. Hold it in the solution for about 5-10 seconds. Some may struggle with achieving a uniform thickness. A consistent dip technique is essential. Inconsistent dips can lead to weak points, reducing protection.

After dipping, hang the item to drain excess plastisol. Allow it to cool. This step solidifies the coating. An industry study indicates that cooling time is crucial for achieving a robust finish. Rushing can result in flaws. A good practice is to inspect the coating for imperfections before finalization. Reflect on these steps. They are simple, yet mistakes can diminish results significantly.

Plastisol dip coating is an effective technique for protecting various surfaces. To begin this process, you need essential equipment and materials. Start with a suitable dip tank. This tank should hold enough plastisol liquid. A heating element is also crucial, as it helps maintain the right temperature.

You will also require a stable surface for drying. After dipping, ensure the coated objects are placed upright. This step prevents drips and uneven coating. Safety gear is necessary too. Gloves and goggles protect against splashes. A respirator might be wise if fumes are present.

Quality plastisol material is important for durability. Check for the right viscosity before purchase. You might need additional tools such as a thermometer and a timer. These tools help maintain consistency. Remember, practice makes perfect. The process might not yield flawless results the first time. Don't get discouraged. Each attempt is a chance for improvement.

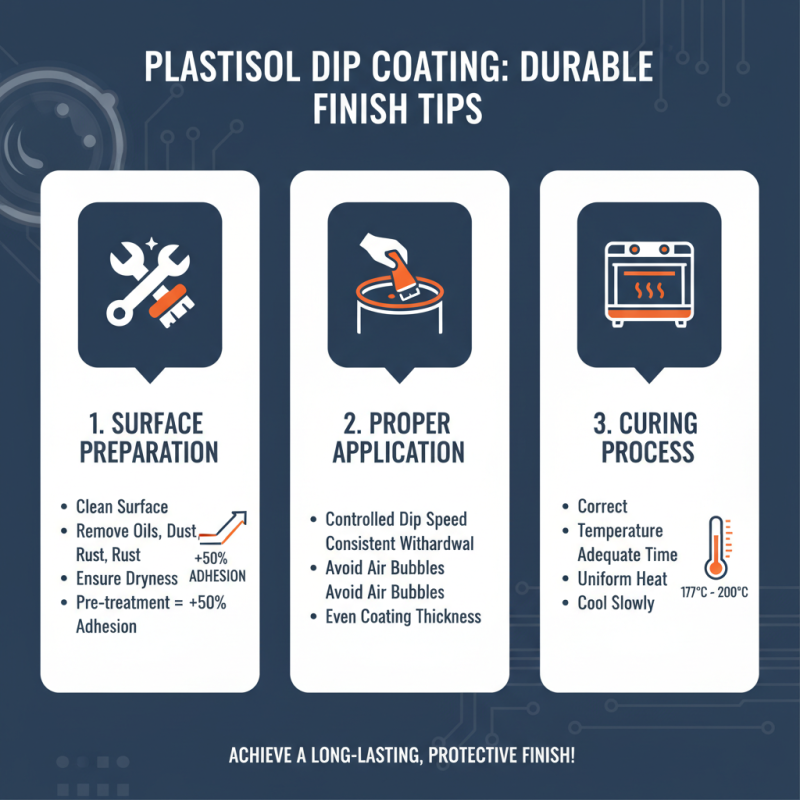

Plastisol dip coating is an effective method for protecting various surfaces. Achieving a durable finish involves several key tips. Proper surface preparation is essential. The surface must be clean and free from oils, dust, or rust. Any contaminants can lead to poor adhesion. A study indicates that pre-treatment can improve adhesion by up to 50%.

Temperature control is also crucial during the dipping process. The optimal temperature for the plastisol should be maintained between 350°F and 400°F. This range helps in creating an even coating. If the temperature is too low, the coating may not cure properly. Inadequate curing can lead to peeling or chipping. Avoid rushing the drying process; patience pays off.

Another important consideration is the thickness of the coat. A typical recommendation is about 10 to 20 mils. Too thin a coat provides insufficient protection. Too thick a coat can lead to drips or uneven surfaces. Each project may require adjustments. Regular testing can help determine the ideal thickness for specific applications. Remember, achieving the perfect finish takes practice and reflection on past attempts.