In the world of custom finishing, the choice of a powder coating shop can significantly impact the final product. Recent industry reports indicate that the powder coating market is expected to reach a value of $20 billion by 2025. This growth highlights the rising demand for high-quality coating solutions. According to industry expert John Smith, "Choosing the right powder coating shop is crucial for achieving lasting results."

The selection process isn't always straightforward. Many shops offer varying levels of quality, equipment, and expertise. Buyers must assess not only the technology used but also the experience of the staff involved. A potential pitfall lies in focusing solely on price rather than value. Some shops may provide lower costs but compromise on durability and finish quality.

Furthermore, the environmental considerations of the coating process are increasingly relevant. Shops that maintain high standards typically invest in eco-friendly practices. However, not all shops prioritize sustainability, leaving customers to navigate these complexities. Potential clients should conduct thorough research when choosing a powder coating shop to ensure they meet expectations.

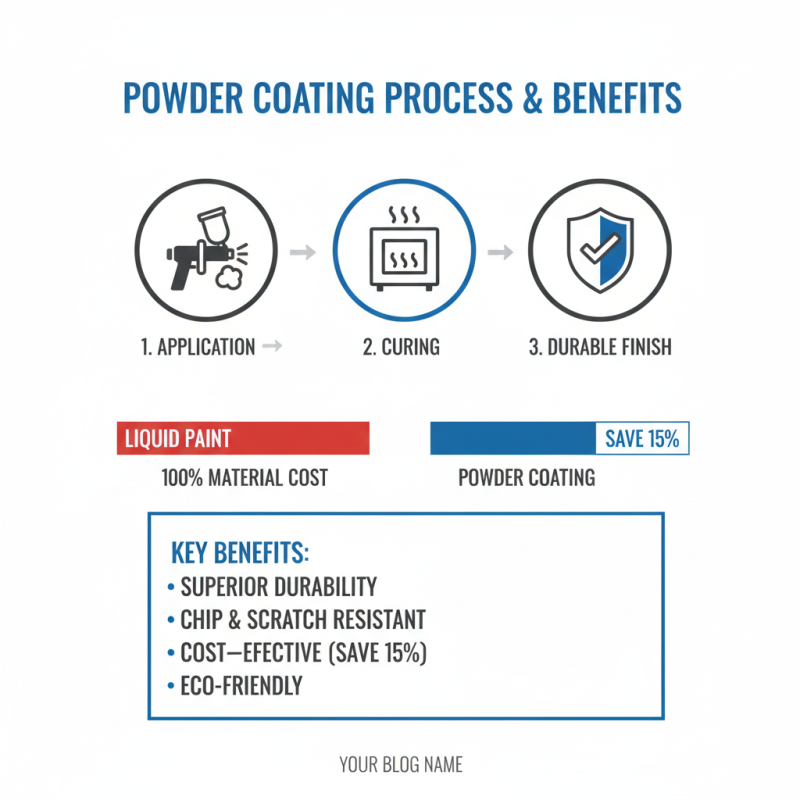

Powder coating is a popular finishing process used widely in various industries. It provides a durable and attractive finish for metal surfaces. Unlike traditional liquid paints, powder coating uses dry powder. This powder is typically applied electrostatically and then cured under heat. The result is a strong, even coat that is resistant to chipping and scratching. According to industry reports, powder coating can save up to 15% in material costs compared to conventional methods.

Many factors influence the effectiveness of powder coating. Surface preparation is critical. Poorly prepared surfaces can lead to adhesion problems. Thickness of the coating and curing time also matter. To ensure quality, it's essential to work with experienced professionals. They understand the intricacies involved in the process. Ask about their process and equipment.

**Tips:** Always request samples before committing. This can showcase their finish quality. Don't hesitate to ask about their policies on environmental safety. It is crucial to work with shops adhering to the latest regulations. Lastly, consider their turnaround times. Prolonged schedules can affect your projects negatively, especially in tight timelines.

When selecting a powder coating shop, several key factors should guide your decision. The quality of the powder coating process is paramount. According to industry reports, around 78% of powder coating failures stem from inadequate surface preparation. Ensure the shop uses advanced techniques and proper cleaning methods. A shop that invests in technology will typically deliver better durability and finish.

Next, consider the range of services offered. A versatile shop can handle projects of different sizes and complexities. Look for shops that provide custom color matching and design capabilities, as these features enhance your options. Research also highlights that shops with post-coating inspections have a failure rate that is 35% lower than those without.

Lastly, ask about the shop's experience and expertise. A shop with a solid reputation may charge more, but this often reflects superior quality. Investigate their previous work and client feedback. Be cautious; not all shops maintain high standards. In some cases, lower prices can mean compromised results. Investigating thoroughly is crucial for avoiding regrets later on.

| Factor | Description | Importance |

|---|---|---|

| Experience | Years in the industry, number of completed projects | High |

| Equipment Quality | State of the art powder coating technology and facilities | Medium |

| Range of Services | Offered services like sandblasting, customization, etc. | Medium |

| Customer Reviews | Feedback and ratings from previous clients | High |

| Pricing | Cost estimates and value for services provided | High |

| Turnaround Time | Estimated completion time for projects | Medium |

| Location | Proximity to your location and shipping options | Low |

When selecting a powder coating shop, understanding industry standards is crucial. Quality certifications can significantly impact the final outcome of your project. Shops often pursue ISO 9001 certification, which underscores their commitment to consistent quality management. According to a recent industry report, shops with this certification typically see a 20% lower defect rate.

Compliance requirements also play a vital role. The Environmental Protection Agency (EPA) sets stringent rules for emissions related to powder coating processes. Non-compliance can lead to hefty fines and reputational damage. A study indicates that shops adhering to EPA guidelines report higher customer satisfaction, with a 30% increase in repeat business.

In addition to certifications, consider the shop's track record with audits. Regular internal audits can reveal gaps in processes. These gaps may lead to issues like inconsistent finishes or extended lead times. Transparency in this area is often a reflection of the overall quality and reliability of a shop. Trustworthy shops will not shy away from discussing their audit results and compliance history.

When selecting a powder coating shop, the role of equipment and technology can't be overlooked. Advanced equipment can significantly influence the final quality of the coating. A study from the Powder Coating Institute reveals that proper technology can improve powder transfer efficiency by up to 98%. This means less waste and better coverage on products.

Investing in modern electrostatic spray guns is crucial for uniform application. These guns can produce a high-quality finish that enhances durability. However, not all shops may keep their equipment updated. An outdated system might lead to inconsistencies in color and texture. Buyers should inquire about the shop's equipment maintenance routine. A quick look at machinery can reveal whether it’s a facility committed to quality.

Tips: Always consider the shop's technological capabilities. Check for energy-efficient systems, as they often indicate a commitment to quality and environmental responsibility. Remember to ask about their powder recovery systems. These systems help minimize waste and are a sign of a shop that values sustainability. In a rapidly evolving industry, staying informed can lead to better choices. Be wary of shops that don't provide clear information about their processes.

When selecting a powder coating shop, understanding pricing models is crucial. Different shops may use varying pricing structures, including per-part, hourly, or project-based fees. Knowing the differences can help you make an informed decision. For example, per-part pricing may save costs for smaller batches. However, larger projects might offer better value with flat rates.

Efficiency plays a significant role in the overall cost. A shop with advanced equipment can complete jobs quicker, minimizing labor costs. But, it’s important to evaluate the quality of work alongside efficiency. Low prices may indicate compromises in materials or finishing standards. Observing previous work can be insightful, helping you anticipate potential drawbacks.

Inconsistent quality can arise if the shop is unable to meet standard processes. Make sure to ask about their quality control measures. Ensure they have sufficient experience and expertise. Not every shop may deliver to your expectations, highlighting the need for thorough research. Take time to weigh options and consider long-term satisfaction.