In the ever-evolving landscape of industrial coatings, the significance of PVC coating has been gaining recognition for its exceptional protective properties and versatility across various applications. According to a recent report by Smithers, the global market for PVC coatings is projected to grow significantly, with an estimated increase of over 7% annually through 2025. This surge is attributed to the escalating demand for durable and resilient materials that can withstand harsh environmental conditions.

Renowned industry expert Dr. Jane Thompson, a leading figure in polymer coatings research, emphasizes the advantages of PVC coating, stating, "The unique properties of PVC coating not only enhance the longevity of underlying materials but also contribute to improved aesthetic qualities and reduced maintenance costs." These benefits are becoming increasingly critical for industries ranging from construction to automotive, where performance and durability are non-negotiable requirements. As we delve into the top ten benefits of PVC coating, it's clear that its role in modern manufacturing processes is not only valuable but essential for sustaining long-term operational efficiency.

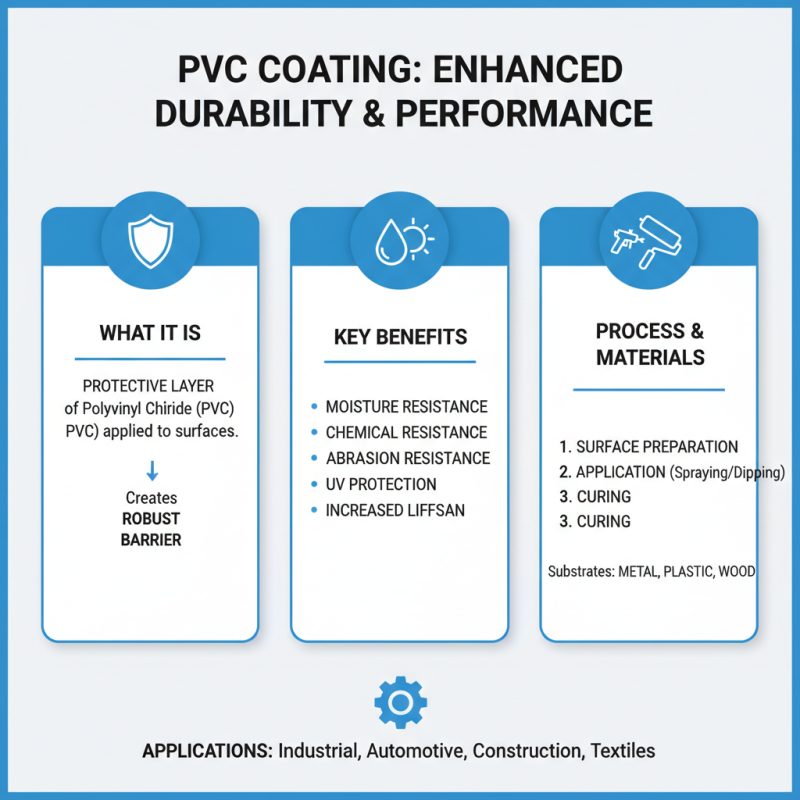

PVC coating is a widely used protective finishing that enhances the durability and performance of various substrates. This type of coating involves applying a layer of polyvinyl chloride (PVC) to surfaces, providing a robust barrier against environmental factors such as moisture, chemicals, and UV radiation. The process typically requires surface preparation, followed by application techniques such as spraying or dipping, resulting in a uniform and resilient layer that adheres well to materials like metal, plastic, and wood.

The advantages of PVC coating extend beyond mere aesthetic improvements; it plays a crucial role in extending the lifespan of products by providing resistance to corrosion and wear. Additionally, PVC coatings can be formulated to achieve specific textures and colors, allowing for versatile applications in different sectors, from construction to automotive. Understanding how PVC coating works is essential for industries seeking to enhance product quality and performance while optimizing maintenance and replacement costs.

PVC coating is widely recognized for its versatile properties, making it an ideal choice across various applications. One of its key characteristics is its exceptional durability. PVC-coated materials can withstand harsh environmental conditions, including moisture, chemicals, and UV exposure, which significantly prolongs their lifespan. This makes it a favorite in industries such as construction, automotive, and electronics, where resilient materials are crucial.

Another important property of PVC coating is its excellent insulation capabilities. It provides effective electrical insulation, which is vital for protecting sensitive components in electronic devices. Furthermore, PVC coatings offer good thermal insulation, helping to maintain temperature control in pipes and cables. The lightweight nature of PVC also contributes to easier handling and installation, enhancing efficiency in manufacturing processes.

Overall, the combination of durability, insulation, and ease of application positions PVC coating as a leading option for a wide range of projects.

PVC coating has gained significant traction in industrial settings due to its robust protective properties. One of the foremost advantages is its exceptional resistance to corrosion. This makes it an ideal choice for equipment and structures that are exposed to harsh environments, as the coating acts as a barrier against moisture and chemicals. Moreover, PVC's durability ensures that tools and machinery can withstand the rigors of daily use, reducing the frequency of replacements and maintenance costs.

Another key benefit of PVC coating is its versatility in application. It can be easily applied to a variety of surfaces, including metals, plastics, and composites, enabling consistent performance across different components in industrial operations. Additionally, PVC coatings can be formulated to enhance slip resistance or provide a non-stick surface, which is particularly beneficial in manufacturing processes. This adaptability not only improves safety but also enhances operational efficiency, making PVC coating a preferred choice among industrial users.

When considering protective coatings for various applications, it's essential to compare PVC coating with alternative options. PVC, or polyvinyl chloride, stands out due to its exceptional resistance against corrosion, UV radiation, and chemical exposure. This makes it an ideal choice for outdoor furniture, electrical cables, and industrial components.

In contrast, alternative coatings such as epoxy and polyurethane may offer similar protective qualities but often fall short in flexibility and adaptability, making them less suitable for environments that experience frequent temperature fluctuations and physical stress.

Furthermore, the application process and longevity also differ between PVC and its alternatives. PVC coating typically involves a straightforward procedure that can be efficiently executed, providing a durable finish that can withstand harsh conditions for an extended period. On the other hand, while epoxy and polyurethane coatings may cure faster, they sometimes require more meticulous preparation and can be vulnerable to chipping or cracking over time.

In sum, while evaluating the best coating for your needs, it becomes clear that PVC offers a unique combination of durability, flexibility, and ease of application that sets it apart from other options available in the market.

When it comes to maintaining the longevity of PVC coated surfaces, proper care is essential. Regular cleaning should be the first step, using a mild detergent and water solution to remove dirt and grime. Avoid abrasive materials that could scratch the surface, as maintaining the integrity of the coating is crucial. A soft cloth or sponge works best for gentle cleansing, ensuring no chemical damage to the PVC layer.

Another important consideration is protecting the coated surfaces from extreme weather conditions. While PVC coatings are designed to withstand various environmental factors, excessive exposure to harsh UV rays can lead to fading. Therefore, when possible, keep such surfaces shaded or apply protective covers during peak sunlight hours. If the PVC coating shows signs of wear, immediate touch-up with the appropriate repair kit can prevent further deterioration and extend the overall life of the coated material. These simple maintenance tips will help you make the most of your PVC coated surfaces, ensuring they remain both functional and aesthetically pleasing.

| Benefit | Description | Maintenance Tip |

|---|---|---|

| Corrosion Resistance | PVC coatings provide protection against rust and corrosion in various environments. | Inspect regularly for any damages and reapply coating as needed. |

| Durability | The coating enhances the lifespan of the material, making it last longer. | Clean the surface periodically to prevent buildup of dirt and debris. |

| Chemical Resistance | Offers protection against various chemicals, making it suitable for industrial use. | Wipe off spills immediately to avoid degradation of the coating. |

| Aesthetic Appeal | Available in various colors and finishes to enhance visual aspects. | Regularly polish the surface to maintain its shine. |

| Low Maintenance | Requires minimal upkeep compared to other coatings. | Use mild detergents for cleaning to avoid damaging the surface. |

| Non-Toxic | Safe for use in environments where food or people are present. | Ensure proper ventilation when applying any cleaning products. |

| Heat Resistance | Can withstand high temperatures without degrading. | Avoid placing hot items directly on the surface. |

| UV Protection | Protects against UV damage, preventing fading and degradation. | Apply UV protectant sprays as needed for extended protection. |

| Versatility | Applicable to a wide range of materials and industries. | Follow manufacturer's guidelines for application on specific materials. |