Selecting the right epoxy coating is essential for achieving the desired results in any project, whether it involves protecting a floor, enhancing a surface, or creating an aesthetically pleasing finish. With a wide array of epoxy coatings available on the market, it can be overwhelming to make an informed decision. Understanding the various factors that influence the performance and suitability of each type of epoxy coating can greatly enhance the longevity and effectiveness of your project.

In this guide, we will explore the top ten tips for choosing the right epoxy coating tailored to your specific needs. From considerations related to environmental conditions and surface types to the desired finish and application techniques, making the right choice ensures that your epoxy coating fulfills its intended purpose while withstanding wear and tear over time. By carefully evaluating these aspects, you can avoid common pitfalls and maximize the benefits of your chosen epoxy coating, ultimately leading to a successful and satisfying project outcome.

When selecting an epoxy coating for a specific project, it is essential to understand the various types available on the market. Epoxy coatings can be classified into several categories, including moisture-cured, solvent-based, and 100% solids epoxies. According to a report by the Global Epoxy Resin Market, the preference for 100% solids epoxy has increased due to its low volatile organic compound (VOC) emissions and superior durability. This type is particularly favored in applications requiring thick coatings, as it provides excellent resistance to chemicals and abrasion.

Moreover, the application environment plays a critical role in selecting the right epoxy. For instance, moisture-cured epoxies are often used in outdoor settings where humidity is a concern, as they can cure properly without the need for an airtight environment. A study from the American Concrete Institute indicates that specific types of epoxy coatings can provide adhesion strengths exceeding 3,000 psi when properly applied to concrete surfaces. This highlights the importance of not only choosing the correct type of epoxy but also ensuring that the surface preparation aligns with the coating's requirements to achieve optimal performance for the intended application.

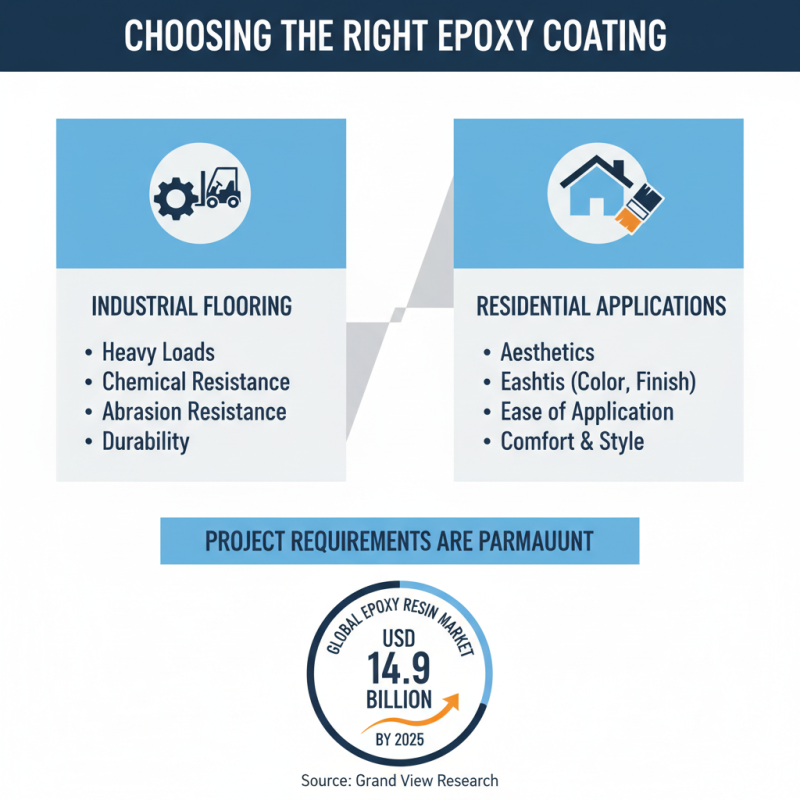

When it comes to selecting the right epoxy coating for your project, understanding the specific requirements is paramount. The unique conditions and demands of your workspace can significantly influence the performance and durability of the chosen epoxy. For example, industrial flooring often requires coatings that can withstand heavy loads and resist chemicals, while residential applications may prioritize aesthetics and ease of application. According to a report by Grand View Research, the global epoxy resin market is projected to reach USD 14.9 billion by 2025, underscoring the increasing demand for tailored solutions that cater to diverse project needs.

Evaluating factors such as substrate type, environmental exposure, and expected wear and tear will aid in making an informed decision. The performance characteristics of different epoxy formulations, including cure time, pot life, and resistance to ultraviolet light, can vary widely. A thorough assessment is essential; for instance, a 2020 market analysis revealed that coatings with enhanced UV stability have seen a 15% increase in demand due to growing awareness regarding long-term durability in outdoor applications. By aligning the epoxy coating choice with the specific requirements of your project, you can ensure an optimal balance between functionality and longevity.

When selecting an epoxy coating for your project, it's essential to evaluate the environmental conditions that can affect its performance. Factors such as temperature, humidity, and substrate condition play a pivotal role in determining how well the epoxy will adhere and cure. For instance, high humidity can lead to moisture entrapment, resulting in compromised adhesion and the potential for blisters in the final coating. Likewise, extreme temperatures can either accelerate curing times or prolong them, causing issues in application and performance if not accounted for.

Additionally, consider the exposure conditions that the epoxy coating will face once applied. Environments with heavy foot traffic, exposure to chemicals, or UV light can significantly influence the longevity and durability of the coating. While selecting the right epoxy, it's crucial to understand these factors and choose a formulation tailored to withstand the specific environmental challenges it will encounter. Assessing these conditions beforehand ensures that your epoxy application will not only adhere correctly but also perform optimally over time, reducing the likelihood of premature failure or the need for reapplication.

When choosing the right epoxy coating for your project, the application method and surface preparation techniques are crucial components that can significantly influence the outcome. The surface must be clean, dry, and free from contaminants such as grease, dust, or old coatings. Proper surface preparation involves mechanical methods like sanding or grinding, followed by thorough cleaning to ensure maximum adhesion. This step not only enhances the durability of the coating but also prevents future peeling or chipping that can occur if the epoxy is applied to a poorly prepared surface.

Additionally, the chosen application method should align with the specifics of your project. For intricate or small spaces, a brush or roller may be more suitable, allowing for precision and control. On larger surfaces, consider using a spray application for an even finish and quicker coverage. Each method requires different levels of skill and tools, and understanding these nuances can help you achieve a professional-looking result. Therefore, it is imperative to evaluate both the preparation and application techniques to select an epoxy coating that meets your specific needs, ensuring your project is both aesthetically pleasing and long-lasting.

When considering epoxy coating options for your project, one of the most crucial factors is budgeting. Aligning your cost with expected quality can significantly affect the outcome of your application. While it may be tempting to opt for the lowest-priced option, this approach can lead to increased costs in the long run due to potential failures requiring reapplication. Finding a balance between cost and quality is essential for achieving lasting results.

One tip for navigating this landscape is to thoroughly research different epoxy products. Not all epoxies are created equal; some offer superior durability and resistance to chemicals, which may justify a higher upfront cost. Before making a decision, assess the specific requirements of your project—this will help you determine what features are worth investing in. Additionally, consider the long-term cost implications; a more expensive but higher-quality epoxy may save you money over time by reducing maintenance and repair needs.

Another important tip is to seek professional advice. Consulting with contractors or industry experts can provide insights into the best epoxy solutions that fit your budget while maintaining quality standards. They can offer recommendations based on experience and common trends, helping you avoid pitfalls in your selection process. Prioritizing both cost and quality will lead to a successful application, ensuring that your project stands the test of time.

| Tip | Cost Range ($) | Quality Rating (1-10) | Recommended Use |

|---|---|---|---|

| Assess Your Needs | Free Consultation | N/A | General Guidance |

| Choose the Right Type | 50 - 100 | 7 | Indoor Projects |

| Consider Application Method | 10 - 50 | 8 | DIY or Professional |

| Evaluate Durability | 100 - 300 | 9 | High Traffic Areas |

| Check for Safety Standards | Varies | 10 | All Applications |

| Factor in Environmental Conditions | 50 - 200 | 8 | Outdoor Projects |

| Review Warranty Options | Free to review | N/A | All Purchases |

| Consider Color and Finish | 20 - 150 | 6 | Aesthetic Projects |

| Seek Professional Advice | 150 - 500 | 9 | Complex Applications |

| Budget for Maintenance | 20 - 100 | 7 | All Projects |