Powder coating has become a popular method for achieving a durable and attractive finish on various surfaces, especially for DIY enthusiasts looking to enhance their projects. According to James Carter, a leading expert in at home powder coating, "The key to success lies in meticulous preparation and the right application technique." This statement encapsulates the essence of what it takes to achieve a professional-looking finish without the need for industrial equipment or facilities.

As more people turn to at home powder coating as a feasible alternative to traditional painting methods, understanding the techniques and tools necessary for success is crucial. From the initial surface preparation to the final curing process, each step is vital in ensuring a flawless result that can withstand the test of time. By following expert advice and utilizing proper safety measures, anyone can transform their home projects into stunning pieces with a factory-like finish.

In this guide, we will explore the essential steps and best practices for at home powder coating, enabling hobbyists and DIYers alike to achieve professional results in their own workshops. Whether you are refurbishing old furniture, customizing automotive parts, or creating art pieces, mastering at home powder coating will elevate your craftsmanship and bring your vision to life.

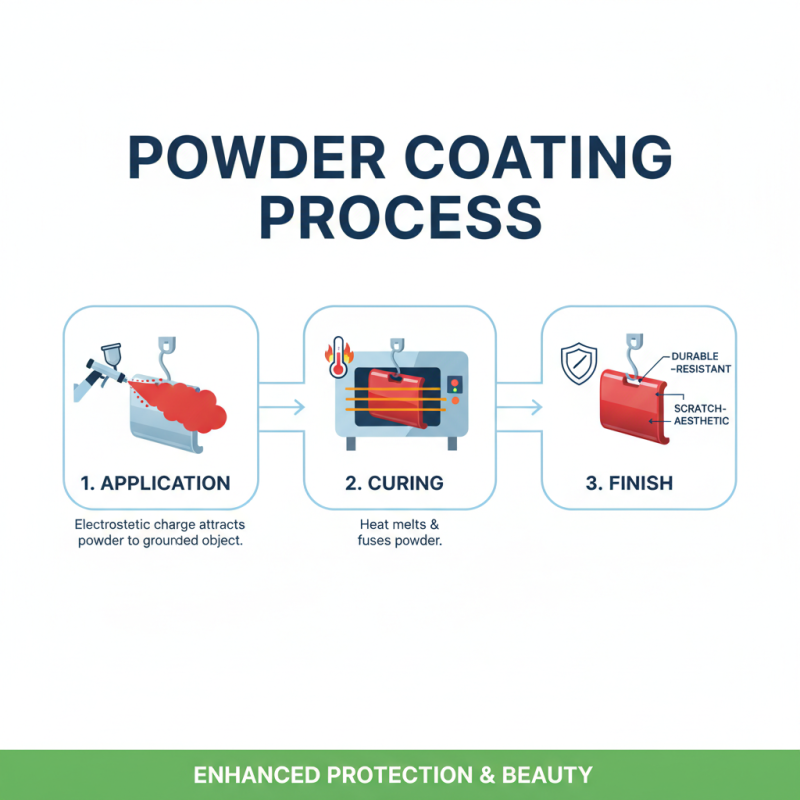

Powder coating is a versatile finishing process that provides a durable and aesthetically pleasing surface on a variety of materials. The fundamental principle behind powder coating involves the application of a dry powder, which consists of finely ground particles of resin and pigment. This powder is electrostatically charged and sprayed onto a grounded object, allowing it to adhere evenly. Once applied, the coated item is heated in an oven, where the powder melts and fuses to form a smooth, hard finish. This process not only enhances the appearance of the item but also offers resistance to scratching, chipping, and fading.

Understanding the applications of powder coating is essential for achieving a professional finish. It is widely used in various industries, including automotive, furniture, and decorative metal works, due to its ability to create a uniform coating that can be customized for different colors and textures. Additionally, powder coating is favored for its environmental benefits, as it produces minimal volatile organic compounds (VOCs) compared to traditional liquid coatings. This makes it a sustainable choice for both industrial and DIY projects. Mastering the basics of powder coating can transform ordinary items into durable and visually appealing pieces, empowering enthusiasts to create impressive results from the comfort of their own home.

When it comes to achieving a professional finish in home powder coating, the right equipment is crucial. Essential tools include a high-quality powder coating gun, an oven specifically designed for curing powder, and a sandblasting setup for surface preparation. According to recent industry reports, the efficiency of a well-calibrated gun can significantly impact the thickness and quality of the powder coating—proper settings can yield up to 20% more even coverage compared to those using less effective equipment.

Additionally, safety equipment cannot be overlooked in the home powder coating setup. A good ventilation system is essential to manage the fumes emitted during the curing process, as well as to ensure a safe working environment. The National Fire Protection Association (NFPA) indicates that proper ventilation and the use of personal protective equipment (PPE) reduce the risks of accidents related to flammable powders. Tools such as a dedicated workspace and high-durability gloves can contribute to a safer and more efficient operation, resulting in a professional finish that stands the test of time. With these essentials in place, DIY enthusiasts can create stunning, durable coatings right at home.

Preparation is crucial for achieving a professional finish when powder coating at home. The first step in the preparation process is to thoroughly clean the surfaces you intend to coat. This typically involves removing all dirt, grease, and oxidation. Studies show that contaminants on the surface can lead to poor adhesion, resulting in an uneven coating or premature failure of the finish. A report by the Powder Coating Institute highlights that proper surface preparation can increase the longevity of powder coatings by up to 50%, making this step essential for both aesthetics and durability.

Once the cleaning is complete, the next phase involves additional surface preparation, which may include sanding or abrasive blasting to achieve a smooth texture. For metals, pre-treatment strategies, such as using a phosphatizing solution, can enhance the coating’s adherence and corrosion resistance. According to a technical paper from the American Coatings Association, applying a pre-treatment can improve the adhesion of powder coatings by creating a chemically bonded surface, significantly reducing the risk of delamination and other failures. Therefore, dedicating ample time and resources to the preparation stages is key to achieving a flawless, professional-looking powder coat finish.

| Preparation Step | Importance | Tools Required | Time Required |

|---|---|---|---|

| Cleaning | Removes dirt and oils for adhesion | Degreaser, Rags | 30 minutes |

| Sanding | Creates texture for better coating bond | Sanding block, Sandpaper | 1 hour |

| Preheating | Eliminates moisture and improves coating flow | Oven or heat gun | 15 minutes |

| Masking | Protects areas not to be coated | Masking tape, Plastic sheeting | 20 minutes |

| Final Cleaning | Ensures no contaminants remain | Lint-free cloth, Isopropyl alcohol | 10 minutes |

Achieving an even coverage and the correct thickness during the powder coating application process is crucial for a professional finish. Begin by thoroughly cleaning and preparing the surface of the object you intend to coat. Any dirt, grease, or oxidation can lead to uneven coverage and poor adhesion. Use a suitable solvent or abrasive method to ensure that the surface is free from contaminants. Once cleaned, perform a thorough inspection to confirm that the surface is smooth and ready for coating.

When applying the powder coat, use an electrostatic spray method for the best results. Adjust the spray gun settings to control the airflow and powder flow rate, as this will influence the application thickness. Start by applying the powder in even, overlapping strokes to cover all areas uniformly. Pay attention to the edges and crevices, as these areas often receive less coating. It's advisable to apply multiple thin layers rather than a single thick coat, as this reduces the risk of runs and drips while helping to maintain a consistent thickness across the entire surface.

After the application, allow the item to cure in accordance with the recommended temperature and time for optimal durability and finish.

When powder coating at home, one of the most critical aspects to ensure a professional finish lies in the curing method employed. Curing is the process that allows the powder to fuse and create a durable, resilient surface. Typically, this is achieved through the application of heat, with the standard curing temperature ranging from 350°F to 400°F, held for approximately 10 to 20 minutes based on the specific powder used. According to industry reports, proper curing significantly enhances the adhesion and durability of the powder coating, with un-cured coats being prone to chipping and fading.

For those attempting powder coating at home, safety considerations must also be a top priority. Proper ventilation is crucial, as the process can release fumes that may be harmful if inhaled. Utilizing a respirator rated for organic vapors and working in a well-ventilated area can minimize health risks. Additionally, ensuring that any materials or substrates are free from contaminants before beginning the powder application prevents poor adhesion and finish quality.

Tip: Always preheat your oven to the desired temperature before placing objects inside. This can lead to more consistent results, as cold substrates can absorb heat unevenly and affect the curing process.

Tip: Invest in a pyrometer to accurately measure the surface temperature of your workpieces, as oven settings might not reflect the actual temperature of the substrate itself. This ensures that you're achieving the optimal curing conditions for a long-lasting finish.