In 2026, PVC coating has become increasingly relevant across various industries. This versatile material is known for its durable and flexible properties. Manufacturers widely use PVC coating for its protective capabilities. The applications range from construction to automotive sectors.

PVC coating provides a layer of protection against weathering and wear. It helps extend the lifespan of products, making it an attractive choice. However, environmental concerns and recycling issues persist. The impact of PVC production raises questions about sustainability. Companies must find balance between performance and ecological responsibility.

As the use of PVC coating grows, innovations emerge. New formulations enhance its properties, improving adhesion and reducing environmental impact. Investors and businesses should stay informed. Understanding the future of PVC coating is essential for making responsible choices. Debate continues around its utility versus potential harm. Reflecting on these aspects is vital for a sustainable future.

PVC coating is a process that enhances the durability of various materials. This thermoplastic is known for its versatility. It provides a robust layer against weather, chemicals, and abrasions. The global PVC coating market is projected to witness a compound annual growth rate (CAGR) of 4.5% through 2026. This growth reflects its rising application in construction and automotive sectors.

In applications, PVC coating is often used for wire and cable insulation. It helps improve fire resistance and insulation properties. In the automotive industry, it protects parts from corrosion. Its application is not without challenges, though. Issues can arise in adhesion and long-term durability under extreme conditions. A study highlighted that about 15% of PVC-coated products showed wear within five years, raising concerns about longevity.

Some industries have explored alternatives but often revert to PVC due to its effectiveness. Professional reports indicate that over 70% of manufacturers still prefer PVC coatings for their cost-effectiveness and reliability. Yet, the environmental impact of PVC raises ethical questions. Ongoing innovation aims to reduce these concerns while retaining PVC's beneficial properties. Balancing performance and sustainability continues to be a critical conversation in the industry.

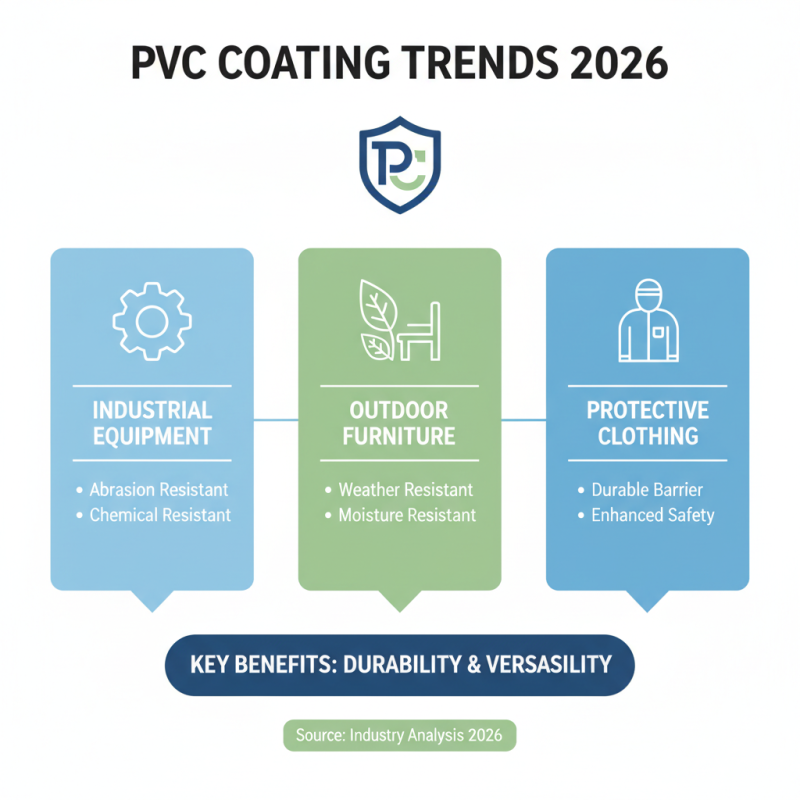

PVC coating is gaining popularity for various applications in 2026. This material is known for its excellent durability and versatility. PVC coating provides a protective layer that enhances resistance against abrasion, chemicals, and moisture. These properties make it ideal for outdoor furniture, industrial equipment, and protective clothing.

One of the key benefits of PVC coating is its ability to withstand extreme weather conditions. It remains stable under UV exposure and maintains its color. This is particularly useful for applications in harsh environments. Additionally, PVC coating is easy to clean and maintain. However, it’s important to consider the environmental impact of the materials used.

Many manufacturers are exploring sustainable alternatives and practices. The use of eco-friendly materials is a growing trend. But not all producers prioritize sustainability, which raises concerns. Balancing performance and environmental responsibility is a challenge. Future developments in PVC technology could address these issues, leading to more innovative solutions.

In 2026, PVC coating finds numerous applications across various industries. One significant use is in constructing outdoor furniture. The coating offers protection against the elements, enhancing durability. Weather resistance is crucial for prolonging the life of these items. However, not all coatings are created equal. Some may wear off quicker than expected, leading to premature damage.

Another common application is in electrical cables. The PVC coating insulates wires, preventing short circuits. This is essential for safety in both residential and industrial settings. Yet, sourcing high-quality materials remains a challenge. Inconsistent quality can pose risks, especially in critical projects. A careful selection can mitigate these issues.

Additionally, PVC coating is widely used in textiles. It provides a waterproof layer, making fabrics suitable for various weather conditions. This application is particularly popular in outdoor gear and tents. Despite its advantages, not every type of PVC coating performs well. Some may lack flexibility, which can lead to tearing. Therefore, testing and research are vital in ensuring the right materials are chosen.

PVC coating is gaining traction in various industries due to its versatility and durability. In 2026, we see creative applications across construction, automotive, and textiles. The coating provides protection against weather elements, corrosion, and wear. For example, in construction, PVC-coated fabrics are used for tents and awnings, enhancing their lifespan.

In the automotive sector, PVC coating is applied to cables and wiring. This helps prevent damage from moisture and abrasion, ensuring better longevity of components. However, there are challenges. Not all PVC coatings are eco-friendly. The production process can raise environmental concerns.

Moreover, in textiles, PVC coating allows for water-resistant clothing. It also adds durability to fashion items. Yet, the breathability of such fabrics can sometimes fall short. Consumers are increasingly demanding more sustainable options. Innovators must find a balance between durability and environmental impact. These industry shifts provoke ongoing discussions about sustainability and alternative materials.

In 2026, the PVC coating industry expected significant advancements. A recent report suggests that this market will grow at a CAGR of 4.8%, reaching approximately $20 billion by 2026. This trend is driven by improvements in sustainability and functionality. Manufacturers are now exploring bio-based PVC alternatives. While this seems promising, questions remain about material durability and lifecycle impacts.

Furthermore, innovations in application techniques are on the rise. Techniques like spray coating and electrostatic application are becoming more prevalent. These methods enhance adhesion and overall performance. However, reports indicate that not all applications meet the expected efficiency rates. The industry must continuously evaluate quality control measures.

Sustainability is a significant focus area. End-user industries demand environmentally friendly solutions. It compels manufacturers to rethink traditional methods. Despite progress, there’s skepticism about the potential trade-offs in performance. Industry experts indicate that while new formulations appear beneficial, they may compromise certain properties, such as chemical resistance. Addressing these challenges will be crucial as PVC coatings evolve.