In the rapidly evolving world of surface finishing, "powder coating dip" has gained significant attention. According to a recent report by MarketsandMarkets, the powder coating market is projected to reach $14.2 billion by 2026, driven by its efficiency and environmental benefits. This method offers a durable and aesthetic finish for various substrates, making it a favored choice in industries ranging from automotive to architecture.

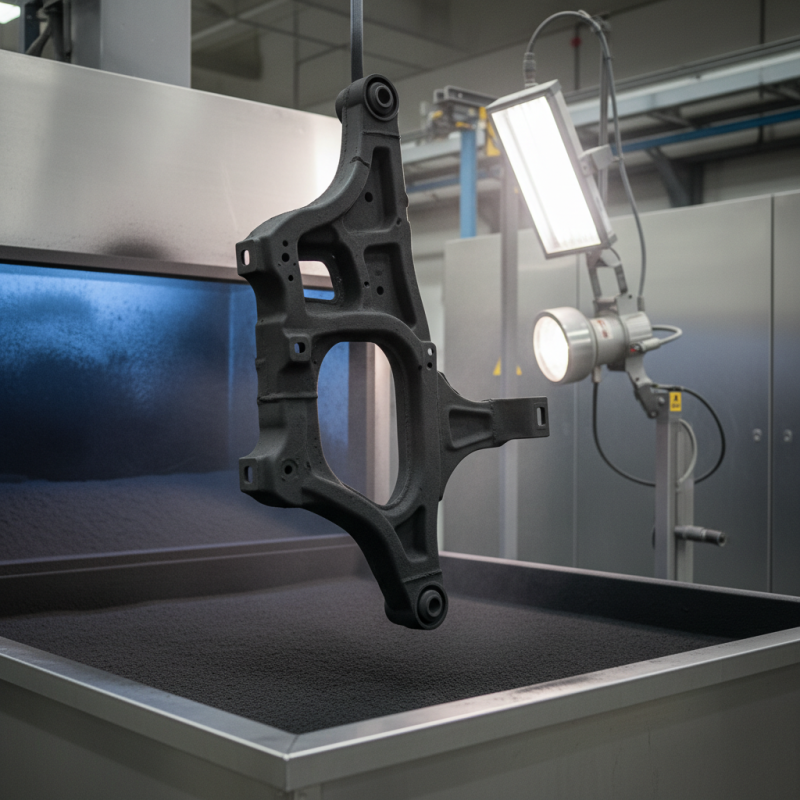

Expert Johnathan Marsh, a renowned figure in coating technology, emphasizes, "Powder coating dip revolutionizes how we approach surface protection." This technique involves immersing objects in a specially formulated powder, which bonds to the surface when heated. However, many manufacturers still face challenges in achieving uniform coverage and adhesion. The complexities of maintaining consistency across various shapes can lead to imperfections.

As industries adapt to new materials and consumer demands, the need for innovation in powder coating dip processes becomes critical. Understanding the limitations and potential pitfalls in application is essential for improvement and growth in this field.

Powder coating dip is a fascinating process used for finishing various objects. This method involves dipping items into a special powder that can easily adhere to surfaces. Once dipped, the item is heated, causing the powder to melt and form a smooth, durable coating. This technique is widely appreciated for its efficiency and effectiveness in creating vibrant finishes.

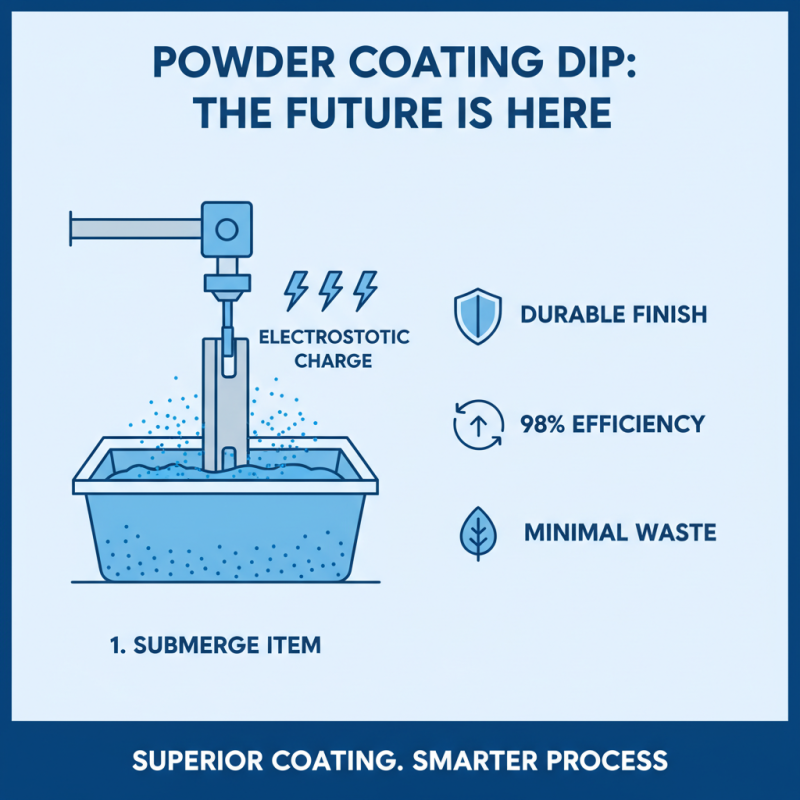

The process begins with thorough surface preparation. Items must be cleaned and prepped to ensure proper adhesion. After preparation, the object is immersed in a fluidized bed of powdered coating material. The powder is charged electrically, which helps it cling to the surface. This step requires precision; a hasty dip can lead to uneven coverage.

After dipping, the coated item is subjected to heat in an oven. The heat causes the powder particles to fuse together, creating a strong bond. However, this phase can present challenges. If not monitored carefully, overheating can lead to bubbles or imperfections in the finish. Observing these details is crucial for achieving a flawless outcome, but blunders can happen. Accepting that refinement is part of the journey can lead to improved techniques and better results over time.

Powder coating dip is a popular method used for finishing metal surfaces. This process involves dipping objects into a container filled with powder. The powder adheres to the surface, creating a durable and attractive finish. The even application ensures that every corner gets coated. It's a cleaner alternative to traditional liquid painting.

During the powder coating dip process, the item is prepped by cleaning and possibly sandblasting. This step is crucial. A clean surface ensures better adhesion of the powder. After the item is coated, it goes into an oven. The heat melts the powder, forming a tough finish. The result is often a smooth, even layer that resists chips, scratches, and corrosion.

Tips: Always wear protective gear when handling powder. A mask and gloves are essential. If you notice uneven coating, you may need to adjust your technique. Air pressure or powder selection might need some tweaks. Experimenting can lead to better results. Take notes on your process to improve each time.

| Step | Description | Duration | Equipment Used |

|---|---|---|---|

| Preparation | Cleaning and preparing the surface to be coated. | 1-2 hours | Sandblaster, cleaning solutions |

| Preheating | Heating the component to help the powder adhere properly. | 30 minutes | Oven or heating chamber |

| Powder Application | Applying electrostatically charged powder to the heated surface. | 15-30 minutes | Powder spray gun |

| Curing | Heating the coated item to fuse the powder into a solid, durable finish. | 10-20 minutes | Curing oven |

| Cooling | Allowing the coated item to cool down to room temperature. | 15-30 minutes | Ambient environment |

Powder coating dip is gaining popularity for its distinctive advantages. This method involves using a dry powder that is electrostatically applied to a surface. After application, the coated item is cured under heat, resulting in a durable finish. According to the Powder Coating Institute, this technique is 2-3 times thicker than traditional paint but maintains a smooth appearance.

One significant benefit of powder coating dip is its environmental impact. This process generates minimal waste. Unlike liquid paints, it releases fewer volatile organic compounds (VOCs). Industry data indicates that powder coating can save up to 90% of resources in some applications. It also provides a tough, resistant finish that can withstand harsh conditions.

Tips: If you’re considering powder coating, ensure the surface is clean. Any dirt or grease can affect adhesion. Also, always apply a test patch to see how colors change after curing. Be cautious, as the process may not be suitable for all materials. Some items might require special handling or preparation.

Another notable aspect is the range of colors and finishes available. Many manufacturers offer custom options. However, achieving exactly what you envision can be tricky. Under certain conditions, colors can appear differently than expected. It's essential to work with experts to get reliable results. In conclusion, powder coating dip provides an eco-friendly, durable solution with some nuances to navigate.

Powder coating dip is gaining traction across various industries due to its durability and aesthetic appeal. This technique involves submerging a product in a fluidized powder that adheres to the surface. Many industries utilize this method, including automotive, aerospace, and furniture manufacturing.

In the automotive sector, powder coating is popular for its ability to resist scratching and corrosion. Reports indicate that nearly 80% of vehicles are treated with powder coating. This process also cuts down on harmful emissions compared to traditional paint. In aerospace, the lightweight nature of powder-coated parts contributes to fuel efficiency, making it an attractive choice in an industry constantly seeking optimization.

Tip: When considering powder coating, ensure the chosen color meets industry standards for durability. Many reports suggest that colors with high UV protection perform better in outdoor applications.

The furniture industry has embraced powder coating as well. It allows for a range of finishes while offering a tough surface that stands the test of time. Not all products are suitable for this method, though. Factors like the shape and material can influence results. Manufacturers need to carefully evaluate these aspects for optimal performance.

Powder coating dip offers a unique method of applying a durable finish to various materials. Compared to traditional liquid coatings, this technique provides advantages that are hard to overlook. The process involves submerging items into a powder-filled tank. Electrostatically charged powder particles adhere well to the surface. This ensures even coating and minimal waste, leading to an efficiency rate of approximately 98%, as reported by industry studies.

Many manufacturers choose powder coating dip over liquid options. Liquid coatings often require solvents, increasing their environmental impact. Powder coating, by contrast, contains no volatile organic compounds (VOCs). This eco-friendliness is a significant advantage, especially with stricter regulations on emissions. Furthermore, the durability and resistance to chipping or fading make powder coatings ideal for outdoor applications. A study by the Powder Coating Institute found that powder-coated finishes can withstand harsh weather conditions better than other coatings.

Tips: When considering powder coating dip, think about your specific needs. Ensure the substrate is prepared correctly for optimal adhesion. Additionally, testing different colors or textures can yield surprising results. Remember that while the process is efficient, achieving a flawless finish may require practice and refinement. This is an area where many operators discover room for improvement.