In today’s automotive world, appearance and protection matter. Car enthusiasts seek options that enhance their vehicles. One of the rising solutions is plastic dip coating for cars. This coating offers a unique blend of style and practicality.

Plastic dip coating for cars transforms color easily. It creates a thin, flexible layer over the original paint. This layer protects against scratches, dirt, and UV rays. Many car owners appreciate its versatility. Imagine choosing a bright blue one day and matte black the next. The choice feels limitless.

Despite its benefits, there are challenges. The application process demands precision. Uneven coats can lead to unsatisfactory finishes. Ultimately, weighing the pros and cons is essential. A perfect top coat might not exist, but plastic dip coating presents a valuable option worth considering.

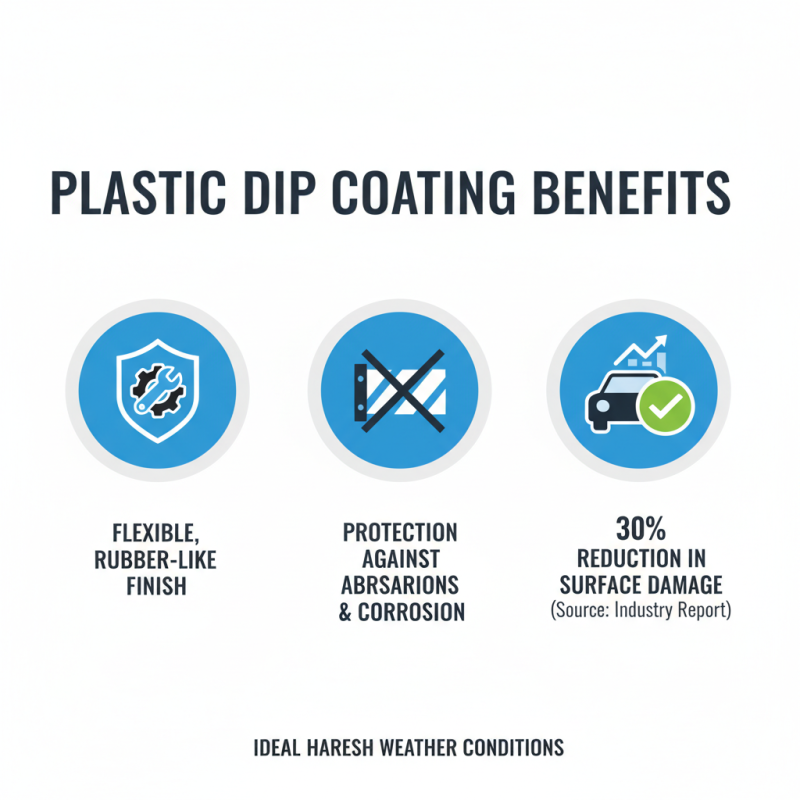

Plastic dip coating offers significant benefits for vehicle protection. This versatile coating provides a flexible, rubber-like finish that acts as a barrier against abrasions and corrosion. According to a report from a leading coatings industry publication, vehicles treated with plastic dip coatings show a remarkable 30% reduction in surface damage over time. This can be particularly important for those living in areas with harsh weather conditions.

The application process is straightforward, which makes it accessible for both professionals and DIY enthusiasts. A report indicated that DIY users accounted for a 40% increase in the market for plastic coatings in recent years. The ability to customize colors and finishes allows car owners to express their personal style. However, it is essential to note that improper application can lead to uneven surfaces or premature wear. Research highlights that achieving a perfect finish requires attention to detail and practice, which some users may overlook.

Long-term durability is another advantage. Studies suggest that vehicles coated with high-quality plastic dip can maintain their protective layer for several years. Yet, regular inspection and maintenance are crucial. Over time, exposure to UV light and moisture may compromise the coating’s effectiveness. Users should evaluate their vehicle's condition periodically, as neglect can lead to significant wear. Balancing aesthetics and functionality is key to maximizing the benefits of plastic dip coating.

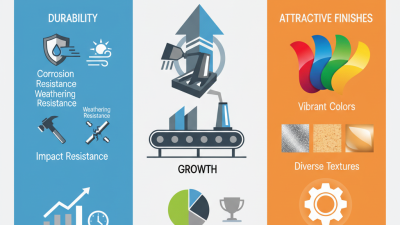

Plastic dip coating is becoming popular in the automotive industry. It offers several practical applications. Car enthusiasts and professionals alike appreciate its versatility. This coating provides a protective layer that can withstand harsh conditions. It's commonly used for vehicle customization, giving cars a unique look.

One common use is on rims. By coating rims with this material, a car owner can enhance its aesthetic appeal. It also protects against corrosion and minor scratches. Interior components also benefit from plastic dip. Steering wheels and dashboards can be coated for better grip and protection.

**Tips:** When applying plastic dip, ensure the surface is clean and dry. This improves adhesion and durability. Avoid extreme temperatures during the application process. It's important to re-evaluate the coating every few months. Certain environmental factors can wear it down.

Plastic dip coating and traditional painting techniques have distinct differences in automotive applications. Plastic dip provides a unique, flexible coating that can be easily removed. This feature attracts many car owners seeking customization. According to a report by the Automotive Coatings Association, about 30% of vehicle owners prefer removable solutions for their cars.

In contrast, traditional paint offers durability but lacks the flexibility of plastic dip coatings. Once applied, it is challenging to extract. The same industry report indicates that traditional paint jobs can cost 25-30% more than dip applications. The longevity of traditional paints can also be affected by environmental conditions. For instance, UV rays can fade finishes, while plastic dip maintains its color longer. However, the durability of plastic dip under extreme conditions is still debatable.

Plastic dip does require a skillful application for a smooth finish. Many DIY applicators struggle with achieving even coatings. This inconsistency can lead to uneven textures and peeling over time. Additionally, while plastic dip is weather-resistant, it may not withstand high temperatures as well as some traditional paints. Understanding these details can help car owners make informed decisions about their vehicle’s finish.

When it comes to plastic dip coating for cars,

durability is a key feature. This coating can withstand harsh weather conditions,

such as extreme heat and cold. It offers a thick, protective layer that resists scratches,

chemicals, and other damage. For many car owners, this means fewer trips to repair shops. However, one must consider

the initial application process carefully. If applied incorrectly, it might not adhere well and could peel off prematurely.

Maintenance of plastic dip coated surfaces is relatively straightforward. Regular washing is essential to maintain its appearance.

Using gentle soaps preserves the coating's integrity. Still, be cautious with high-pressure washers; they can cause

unintended damage. Some users note that over time, the coating may fade or lose its luster. Reapplying the coating

ensures continued protection. This points to the necessity of regular evaluations, as neglect can lead to costly refinishing.

Additionally, while the coating provides excellent protection, not every surface is suitable for this application.

Some intricate designs or textures may not work well. It's important to reflect on the specific needs of your vehicle

before committing. Overall, while plastic dip coating offers numerous benefits, careful consideration and maintenance

play significant roles in maximizing its potential.

Plastic dip coating offers a cost-effective solution for vehicle customization. Many car enthusiasts seek unique finishes. This method provides an easy way to achieve that. Unlike traditional paint, plastic dip is less expensive. It allows for vibrant colors using fewer resources. This appeals to those on a budget.

Application is simple and can be done at home or in a garage. The process requires minimal preparation. However, some may struggle with the technique. Getting an even coat can be tricky. Mistakes may lead to unsatisfactory results. Experimentation will be necessary to find the right thickness.

Durability is a factor worth considering. While plastic dip is resistant to elements, it may not last as long as paint. It is removable, allowing for easy changes. This flexibility can be very appealing. Yet, it requires regular maintenance to keep it looking sharp. Investing in quality materials is also crucial for the best outcome.