Dip coating is an essential technique in the coatings industry, offering unique advantages for various applications. According to Dr. Emily Carter, a leading expert in surface engineering, “Dip coating provides a seamless coverage that is hard to achieve with other methods.” This method immerses an object in a liquid coating material, ensuring an even distribution. The process is widely used in industries, from automotive to electronics, showcasing its versatility.

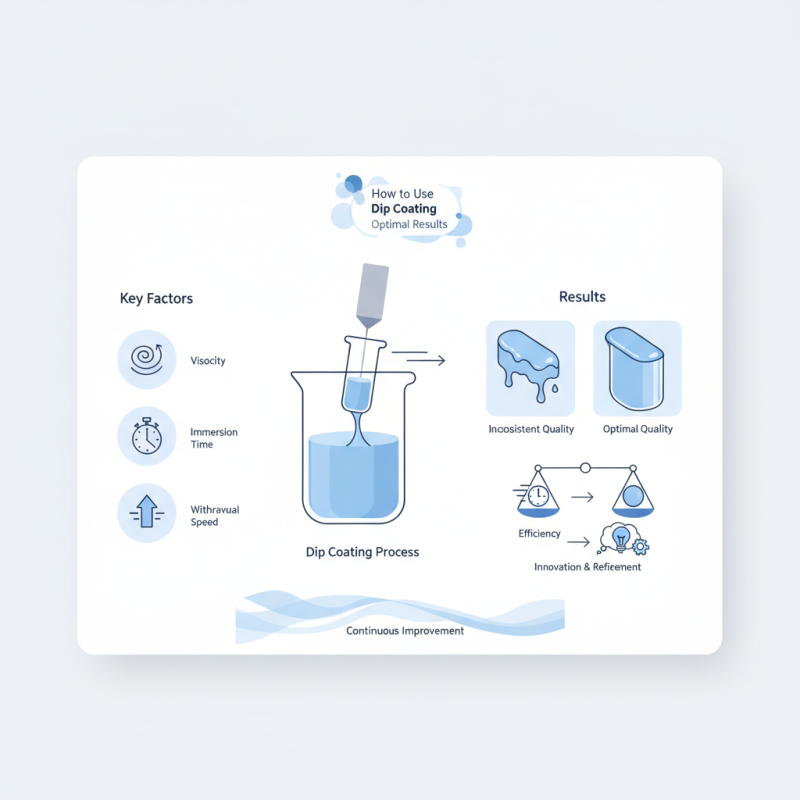

However, achieving optimal results with dip coating requires precision and understanding of the materials used. Factors like viscosity, immersion time, and withdrawal speed can determine the final product's quality. Often, companies overlook these details, leading to inconsistent results. Improvement means valuing every step in the dip coating process.

The challenge is to balance efficiency and quality. Many practitioners find themselves rushing, which can compromise results. Reflecting on these practices can foster growth and lead to innovative solutions in dip coating. The aim is to refine the process continually, ensuring that quality remains paramount. This balance is key for professionals seeking to harness the full potential of dip coating.

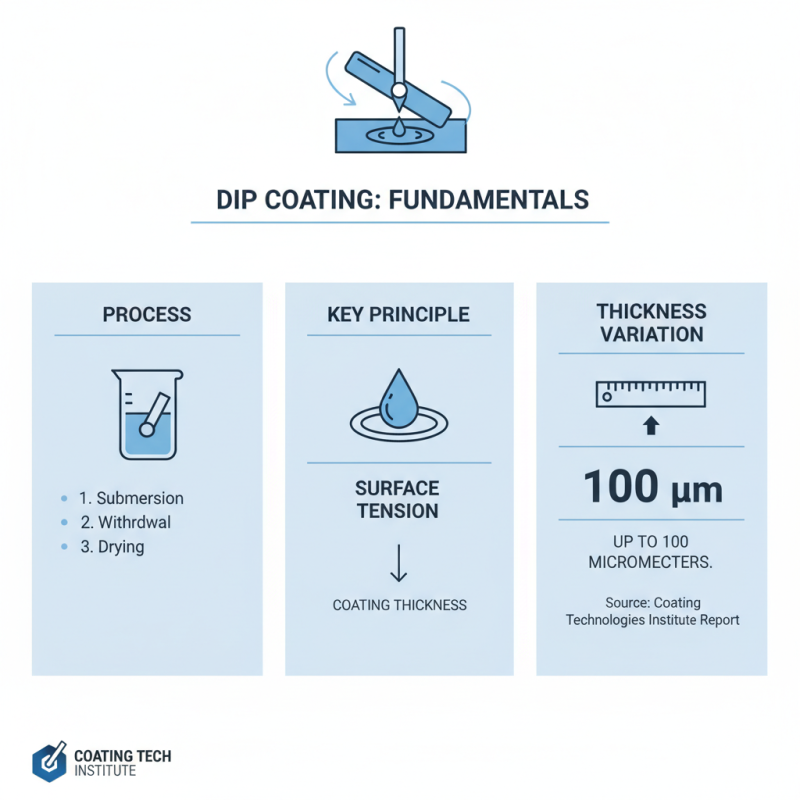

Dip coating is a process widely used in various industries. Its success relies on understanding its fundamental principles. When an object is submerged in a coating solution, surface tension plays a critical role. This principle affects the thickness of the coating. According to a report from the Coating Technologies Institute, the thickness can vary significantly, sometimes measuring up to 100 micrometers.

Achieving optimal results requires careful attention to parameters like withdrawal speed and viscosity of the coating solution. Faster withdrawal speeds often lead to thinner coatings. However, this could result in insufficient coverage on complex geometries. A study published in the Journal of Coating Science indicated that a withdrawal speed of 10 cm/min was ideal for achieving uniform coatings on intricate parts. Every application is unique, and adjustments must be made based on specific needs.

Environmental factors also contribute to the coating's effectiveness. Humidity and temperature can affect drying times and final appearance. Inconsistent drying can lead to defects, such as uneven surfaces. Investment in a controlled environment is necessary for high-quality results. Reflection on these principles is vital, as each dip coating process is a learning opportunity.

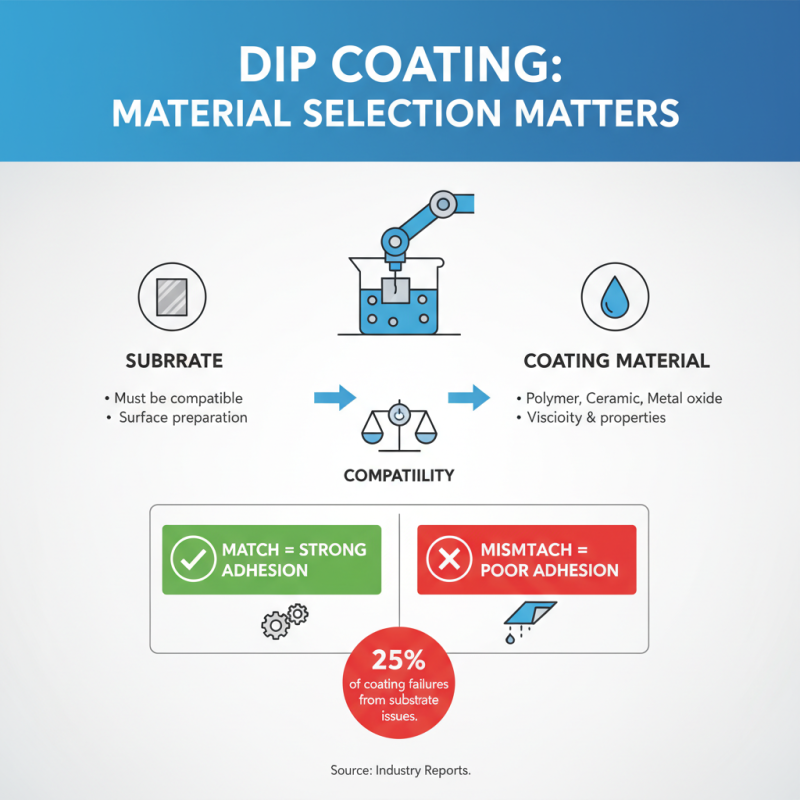

Materials selection is crucial in dip coating. The substrate must be compatible with the coating material. A mismatch can lead to poor adhesion. For instance, according to industry reports, approximately 25% of coating failures stem from substrate issues. This highlights the need for careful selection.

Common substrates include metals, plastics, and ceramics. Each material has its own surface characteristics. Metals can provide excellent durability. However, they may require pre-treatment to enhance adhesion. Plastics are lighter, but they might not hold coatings as effectively. In some cases, a surface primer may be necessary.

The choice of coating is equally important. Water-based coatings offer an environmentally friendly approach. However, they may not perform well in extreme conditions. Solvent-based coatings can provide better durability but may pose health risks. Approximately 30% of coatings in harsh environments fail due to inappropriate selection. This indicates the need for further research and testing.

Dip coating is a widely used technique for applying coatings to various surfaces. The process parameters play a crucial role in achieving desired outcomes. Notably, temperature, immersion speed, and coating thickness significantly impact the final result.

Temperature affects the viscosity of the coating material. Higher temperatures can lead to thinner coatings. However, excessive heat may cause uneven distribution. It's essential to find a balance. Testing different temperatures helps determine the optimal range for your specific application.

Immersion speed is another key factor. Slower speeds allow for thicker coatings, while faster speeds tend to produce thinner layers. However, too slow can lead to dripping and runs. Therefore, adjusting the immersion speed is critical for achieving the intended thickness. Consistent experimenting is necessary to find the right speed for your project.

Coating thickness also varies with the material used. Different substrates may react differently. Sometimes, achieving uniform thickness can prove challenging. Uneven surfaces might require additional adjustments. Observing the results and refining the approach helps improve the process over time.

Dip coating is a widely used process in the coatings industry. It offers a simple way to achieve uniform coverage on various surfaces. To optimize dip coating methods, several factors must be considered.

First, the viscosity of the coating solution plays a crucial role. A report from the Coatings Research Institute states that using a viscosity of around 1000 cP often yields optimal results. This viscosity helps achieve even coverage without excessive drips or pooling. However, achieving the ideal viscosity can be tricky. It's essential to conduct trial applications to find the right balance.

Temperature control is another key aspect. The ambient temperature can affect the drying rate. For instance, a study published in the Journal of Coating Technology found that a temperature range of 20-25°C maximizes adhesion and prevents defects. The challenge lies in maintaining stable conditions, especially in fluctuating environments. Even small changes can impact the final finish. A consistent approach to monitoring environmental factors is necessary for successful dip coating.

| Parameter | Description | Optimal Value | Impact on Coating |

|---|---|---|---|

| Viscosity | Thickness of the coating solution | 100-200 cP | Impacts thickness and uniformity |

| Dip Speed | Rate at which the substrate is submerged | 10-20 mm/s | Affects coating thickness and texture |

| Drying Time | Time between dips or after coating | 5-15 minutes | Determines property development |

| Temperature | Ambient conditions during coating | 20-25 °C | Influences viscosity and drying |

| Substrate Preparation | Cleaning and surface treatment | Maximized adhesion | Crucial for coating performance |

Dip coating is a widely used technique in the coating industry, but it comes with its challenges. One common issue is achieving uniform coating thickness. According to a recent industry report, achieving a consistent thickness can vary by as much as 50% due to factors like immersion speed and withdrawal rate. To mitigate this, operators should closely monitor these parameters and adjust as needed.

Another challenge in dip coating is managing the viscosity of the coating solution. High viscosity can lead to difficulties in application, while low viscosity may result in sagging or dripping. A study showed that maintaining viscosity within a specific range, typically between 100-300 cP (centipoise), can significantly improve adherence and finish quality. Regular testing and adjustment of the coating solution can help in maintaining optimal results.

Additionally, air bubbles can become trapped during the dip coating process, leading to surface imperfections. Proper degassing techniques can remove these bubbles before application. A solution like using vacuum chambers can effectively eliminate air pockets. However, this adds an extra step to the process and requires careful setup. Each of these challenges requires thought and reflection, as adjustments may lead to better overall performance in dip coating applications.