Fluid bed technology stands at the forefront of innovation in various industries. As we approach 2026, its applications are expanding rapidly. Dr. Emily Stone, a leading expert in fluid bed technology, states, “Fluid bed systems transform how we process materials, enhancing efficiency and consistency.” This highlights the significant role that fluid bed technology plays in improving production processes.

Fluid bed systems utilize the principle of fluidization, allowing particles to behave like a fluid. This leads to uniform heating and mixing, essential for industries like pharmaceuticals and food processing. The ability to control temperature and humidity is a game-changer. Companies explore fluid bed applications to optimize quality and reduce waste. However, it’s not without challenges. Implementing fluid bed technology can be costly, and not every organization has the means or expertise.

As we look to the future, these hurdles must be addressed. Can industries fully harness the power of fluid bed technology? With continued research and development, the answers might unfold soon. Understanding both the benefits and limitations of this technology is crucial for progress. The journey towards a more fluid and efficient production landscape is just beginning.

Fluid bed technology represents a unique method of processing materials. It utilizes a fluidized state where particles are suspended in air. This technique enhances the uniformity of heat and mass transfer. The process often takes place in a specially designed chamber. Here, airflow passes through a bed of particles, lifting and agitating them. The results can be impressive, but they require precise control.

Applications of fluid bed technology are varied and interesting. In pharmaceuticals, it ensures even coating and granulation of drugs. In food processing, it aids in the consistent drying of ingredients. However, achieving perfect results can be tricky. Factors like humidity and particle size play crucial roles. Mistakes can lead to poorly coated products or inefficient drying. The technology holds great potential but requires constant optimization and monitoring.

In addition to these common applications, fluid bed systems are also used in chemical production. The ability to handle different materials adds to its versatility. Yet, not every operation is a success. Equipment can suffer from issues like bed collapse or channeling. Continuous evaluation is necessary to overcome these challenges. Fluid bed technology has proven effective but demands attention to detail for the best outcomes.

Fluid bed technology is a fascinating method that utilizes the principles of fluid dynamics to enhance various processes. A fluid bed system consists of a container where particles are suspended by a fluid, usually air or liquid. The flow of the fluid allows for efficient heat and mass transfer, making it an ideal choice for processes such as drying, coating, and granulation.

One of the critical mechanisms at play in fluid bed systems is the concept of uniformity. When particles are fluidized, they achieve a homogenous state, leading to even treatment. This is particularly important in applications like pharmaceutical formulation, where consistency can impact efficacy. However, maintaining this uniformity is challenging. Variations in particle size or moisture content can disrupt the fluidization process.

**Tip:** Regular monitoring of particle characteristics will help maintain uniformity in the bed. Small adjustments in airflow may be necessary to keep everything balanced.

Fluid bed technology is also used extensively in food processing, thanks to precise temperature control. Inconsistent heating can lead to uneven cooking and quality differences. Using temperature probes can enhance accuracy but requires regular calibration to ensure they function correctly. This aspect often gets overlooked but is essential for achieving desired results.

**Tip:** Keep a log of your temperature readings. This practice can help you spot trends and anomalies in the system.

Fluid Bed Technology is revolutionizing several industries by offering unique advantages. This process allows solid particles to be suspended in air, creating a dynamic system. The result is efficient heat and mass transfer, enhancing productivity. In the pharmaceutical sector, studies show that over 60% of drugs are produced using this technique. These systems ensure uniform particle size and consistent quality in formulations.

In food processing, the application of fluid bed technology improves drying and coating processes. Reports indicate that it can reduce drying times by up to 30%. This benefit translates into energy savings and lower production costs. However, challenges exist. The initial setup can be expensive, making it hard for smaller companies to adopt this technology.

Moreover, in the chemical industry, the technology is used for effective granulation and agglomeration. Advanced models accommodate larger batch sizes, but scalability remains a concern for many firms. The balance between high output and product consistency requires careful management. Companies must assess their specific needs and capabilities before implementation.

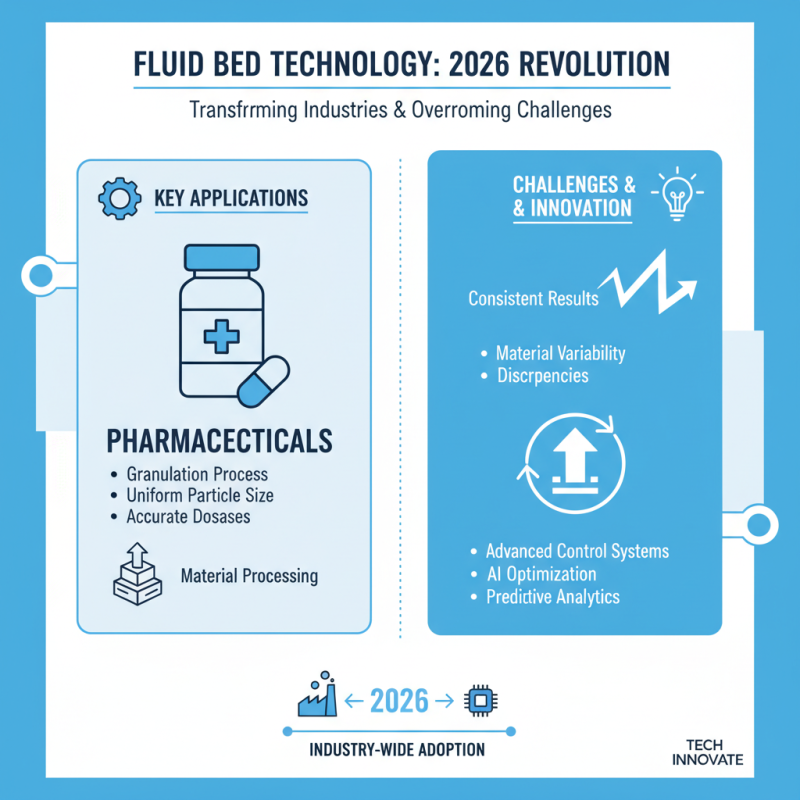

Fluid bed technology has gained popularity in various sectors due to its unique characteristics. In 2026, the technology is set to revolutionize multiple industries. One key application is in pharmaceuticals. The fluid bed process is used for granulation. This process ensures a uniform particle size, crucial for accurate dosages. However, achieving consistent results can be challenging. Variability in materials may lead to discrepancies.

Another significant application is in food processing. This technology enhances things like drying and coating. It helps achieve a uniform texture and flavor. For instance, snack foods benefit from a crisp coating. Nevertheless, controlling humidity levels is vital. Poor control might lead to less desirable outcomes.

In the chemical industry, fluid bed technology is critical for catalytic processes. It allows for effective heat transfer and mixing. These traits enhance reaction efficiency. Yet, operators must consider particle behavior. Proper adjustments can prevent operational setbacks. This industry is exploring improvements, but there are hurdles to overcome. Fluid bed technology demonstrates promising applications, but it is an evolving field.

Fluid bed technology is evolving rapidly. As industries seek efficiency, this method is gaining attention. According to a report by MarketsandMarkets, the fluid bed market is projected to reach $5.7 billion by 2026, reflecting a 5.4% CAGR. This technology is particularly useful in pharmaceuticals, food processing, and chemical production.

One notable trend is the integration of automation. Automated systems enhance precision in fluid bed operations. This leads to more consistent product quality and better resource savings. Additionally, processes like granulation and agglomeration are becoming more streamlined through innovations in monitoring techniques. Companies are also exploring energy-efficient designs to reduce environmental impact.

However, challenges remain. The complexity of fluid bed systems can lead to operational inefficiencies. Training staff to use advanced technology is crucial yet often overlooked. Moreover, issues with scale-up processes can hinder production expansions. Addressing these hurdles will be key for the future of fluid bed technology.