Dip powder coating is a unique finishing technique widely used in various industries. This method involves immersing parts into a powder coating material, which adheres to the surface. As a result, it creates a durable and attractive finish. The process is efficient and often preferred for its effectiveness.

The dip powder coating method offers many advantages. It provides a uniform layer and excellent coverage. However, achieving the perfect finish requires specific conditions. Improper setup can lead to issues. For instance, uneven coating or powder clumping may occur. It prompts a need for careful adjustments.

Understanding dip powder coating is essential for businesses. This knowledge can enhance product quality. Yet, challenges persist. Each step in the process shapes the final appearance. Striking the right balance makes a significant difference. Embracing this technique means recognizing both its strengths and areas for improvement.

Dip powder coating is a popular finishing process that provides a durable and attractive surface for various materials. It starts with a powder made from resin and pigment. This powder is heated to create a smooth, solid finish when it cools down. The process is efficient and environmentally friendly.

During dip powder coating, items are immersed in a fluidized bed of powder. The powder clings to the surface due to electrostatic attraction. After dipping, the coated item is cured in an oven. The heat causes the powder to melt, forming a hard skin.

This coating process has some challenges. Achieving an even coat can be tricky, especially on intricate shapes. Uneven layers can lead to issues later on.

This method is used in various industries, from automotive to household products. Many changes improve durability and adhesion. However, quality control remains essential throughout the process. Not all coatings perform the same. Different environments can affect longevity. It is crucial to choose the right powder for each application.

Dip powder coating has an interesting history. It began in the mid-1950s as a solution for creating durable finishes. Initially, it was used primarily in industrial applications. Over the years, the technique evolved and gained popularity among various manufacturers.

Throughout the 1960s and 1970s, dip powder coating expanded into different sectors. Companies sought ways to improve efficiency and reduce waste. Despite these advancements, some challenges remained. For instance, achieving uniform thickness was sometimes tricky. Furthermore, the environmental impact of certain powders prompted further innovation.

By the 1990s, dip powder coating became more refined. New technologies emerged to enhance adhesion and durability. Today, it offers a wide range of colors and finishes. Yet, some users still report inconsistencies in application. Reflecting on these issues can lead to better practices and satisfied clients.

Dip powder coating is a unique process for finishing metal surfaces. It involves immersing objects in colored powder. This method creates a durable and attractive finish. Here, we will explore the dip powder coating process step-by-step.

The first step is surface preparation. The object needs to be cleaned thoroughly. Any dirt, oil, or rust can affect adhesion. This might require sandblasting or chemical cleaning. It's crucial to get this part right. Take your time here. A clean surface makes a significant difference.

Next, the object is dipped into a fluidized bed of powder. The powder clings to the surface due to electrostatic charges. After dipping, the object is inverted to remove excess powder. Once done, the coated object needs curing. This occurs in an oven at controlled temperatures. Proper curing ensures a strong bond with the substrate.

**Tip:** Always check the temperature settings in the oven. Too high or too low can affect the finish.

After cooling, inspect the final finish. Some items may require a second layer. If the finish isn’t even or if there are imperfections, rethink your process. Sometimes, it means going back to the cleaning stage.

**Tip:** Document your process for better results in the future. Each step is crucial for achieving a perfect finish.

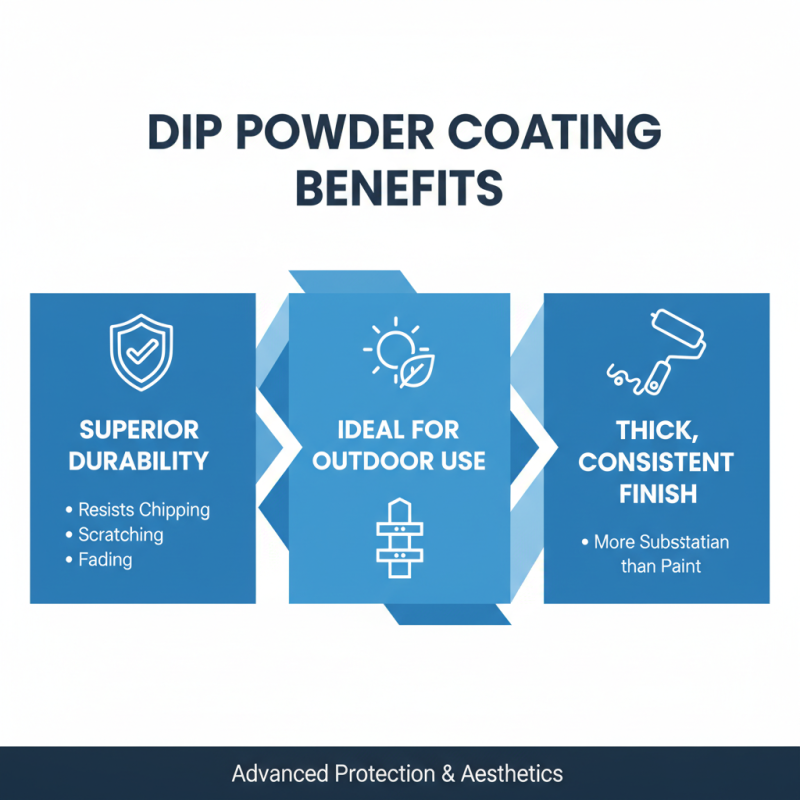

Dip powder coating is an effective finishing method with several benefits. One key advantage is its durability. Items coated with dip powder resist chipping, scratching, and fading. This makes them ideal for outdoor use. In addition, dip powder coatings are thicker than traditional paint, providing a more consistent finish.

Another benefit is the eco-friendliness of dip powder coating. Unlike liquid paints, it produces fewer volatile organic compounds (VOCs). This results in a safer working environment. Moreover, excess powder can be recovered and reused. This reduces waste and conserves materials.

Tips: Ensure proper surface preparation before applying dip powder. Cleaning surfaces removes contaminants that can interfere with adhesion. Experiment with different powder colors to achieve unique finishes. Don't be afraid to make mistakes. Each project is a learning opportunity, refining your technique over time.

Dip powder coating is gaining popularity across various industries. This method offers a durable finish. It's particularly useful for items exposed to harsh environments. For instance, automotive parts often utilize this technique. The application process allows for an even coat that resists chipping and scratching.

In the furniture industry, dip powder coating enhances items like metal frames and outdoor furniture. These products benefit from a variety of colors and textures. This versatility attracts designers looking for unique finishes. However, achieving the perfect coat can be tricky. Variations in temperature and application time may lead to imperfections.

Electronics manufacturers also employ dip powder coating. It protects sensitive components without adding significant weight. Still, not all types of electronics can withstand the process. Careful consideration is required to avoid damaging delicate parts. Understanding the specific needs of each application is crucial for success.