Dip powder coating is a revolutionary finishing process that has gained significant popularity in various industries due to its outstanding durability and aesthetic appeal. This technique involves immersing an object in a fluidized bed of powder, allowing for an even and complete coating that adheres effectively to the surface. As manufacturers and consumers increasingly seek reliable solutions for enhancing the lifespan and appearance of products, understanding the benefits and the intricate process of dip powder coating becomes essential.

The advantages of dip powder coating extend beyond its visual appeal. This method offers excellent resistance to scratching, chipping, and fading while being environmentally friendly compared to traditional liquid paints. Furthermore, the versatility of dip powder coating allows it to be applied to a wide array of materials, making it suitable for everything from automotive parts to household items. In this guide, we will delve into the comprehensive benefits, detailed processes, and diverse applications of dip powder coating, enabling users to appreciate its transformative impact across multiple sectors.

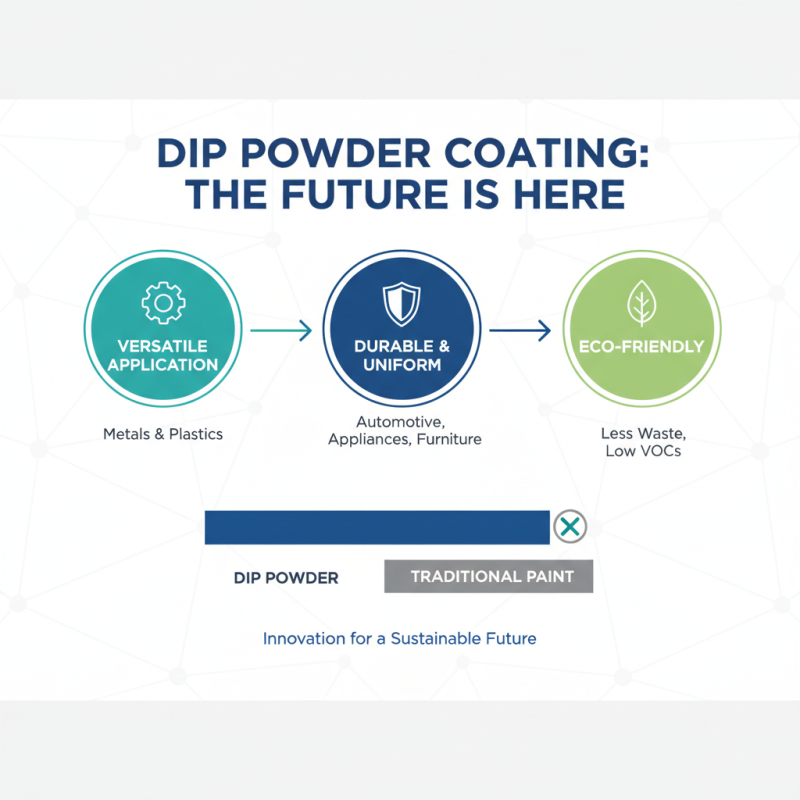

Dip powder coating is gaining popularity across various industries due to its unique advantages. This process provides a uniform coating that is both durable and aesthetically pleasing. One of the key benefits is its versatility; it can be applied to a wide range of materials, including metals and plastics, making it ideal for automotive, appliance, and furniture industries. Additionally, the coating is environmentally friendly, as it generates minimal waste and contains fewer volatile organic compounds (VOCs) compared to traditional liquid paints.

Tips for maximizing the benefits of dip powder coating include ensuring proper surface preparation before application. A clean, well-prepared surface allows for better adhesion and longer-lasting results. It's also advantageous to choose the right type of powder for specific applications, as different formulations can offer various textures and finishes. Regular maintenance can also enhance the longevity of coated items, ensuring they retain both functionality and appearance over time.

Furthermore, it's essential for businesses to consider the cost-effectiveness of dip powder coating. The longevity of the coating combined with reduced labor costs during application makes it a smart investment. Industries looking to enhance their products can leverage dip powder coating to improve performance while also appealing to environmentally conscious consumers. By embracing this technology, companies can stay ahead in a competitive market.

Dip powder coating is an efficient process that provides durable finishes for various substrates. The application begins with thorough surface preparation, which is essential for ensuring the coating adheres effectively. Initially, the item is cleaned to remove any dirt, grease, or oxidation. This can involve washing, sandblasting, or using chemical solvents. Once cleaned, the item should be dried properly to avoid any moisture trapping under the coating.

Once prepared, the next step involves the dipping of the item into a powder coating fluid. The item is submerged in a fluidized bed of powder, allowing the powder to adhere to its surface. After dipping, the excess powder is removed, and the item is then subjected to a curing process through exposure to heat, usually in an oven. This heat activates the resin and helps in forming a strong and durable bond, leading to a smooth and even finish. The entire process is not only efficient in terms of time but also provides superior protection against environmental factors, making it an ideal choice for various industrial applications.

When comparing dip powder coating to traditional coating methods, it is essential to recognize the

substantial advantages dip powder coating offers.

Unlike liquid paints that contain solvents, dip powder coating utilizes a dry powder that can provide several key benefits.

According to a report from the Powder Coating Institute, dip powder coatings can achieve a thickness of

1 to 2 mils in a single application, leading to superior coverage and durability.

This thickness not only enhances the protective features but also ensures a more uniform finish than many traditional

spray or liquid coatings.

Moreover, dip powder coating results in minimal waste due to its recyclability; unused powder can be collected and reused,

making it a more environmentally friendly option.

A study by the Environmental Protection Agency revealed that dip powder coating can reduce volatile organic compound (VOC) emissions

by up to 90% compared to conventional paint systems. This reduction

not only benefits the environment but also improves workplace safety for applicators.

Tips:

When considering which coating method to use, evaluate the

specific needs of your project. If you're looking for a robust finish that provides extra protection against corrosion,

dip powder coating is often the better choice. Additionally, for projects requiring intricate details, traditional methods

may still find relevancy despite the efficiency of dip systems. Always ensure to consult industry standards for the best practices

in coating applications.

Dip powder coating is a versatile finishing process used across various industries due to its durability and aesthetic appeal. Common applications of dip powder coating include automotive parts, where it enhances the resistance to corrosion, scratches, and general wear. By applying a thick, even layer of powdered paint through immersion, manufacturers can achieve a high-quality finish on components such as wheels, chassis, and trim, ensuring they withstand harsh environmental conditions while maintaining a sleek appearance.

In addition to automotive applications, dip powder coating is widely used in the manufacturing of household appliances and furniture. Items such as metal chairs, tables, and kitchenware benefit greatly from this process, providing not only an attractive finish but also improved resistance to chipping and fading. The ability to achieve vibrant colors and textures makes dip powder coating an ideal choice for designers looking to create visually appealing products that maintain their integrity over time. Overall, dip powder coating proves to be a valuable solution across various sectors, enhancing both function and form.

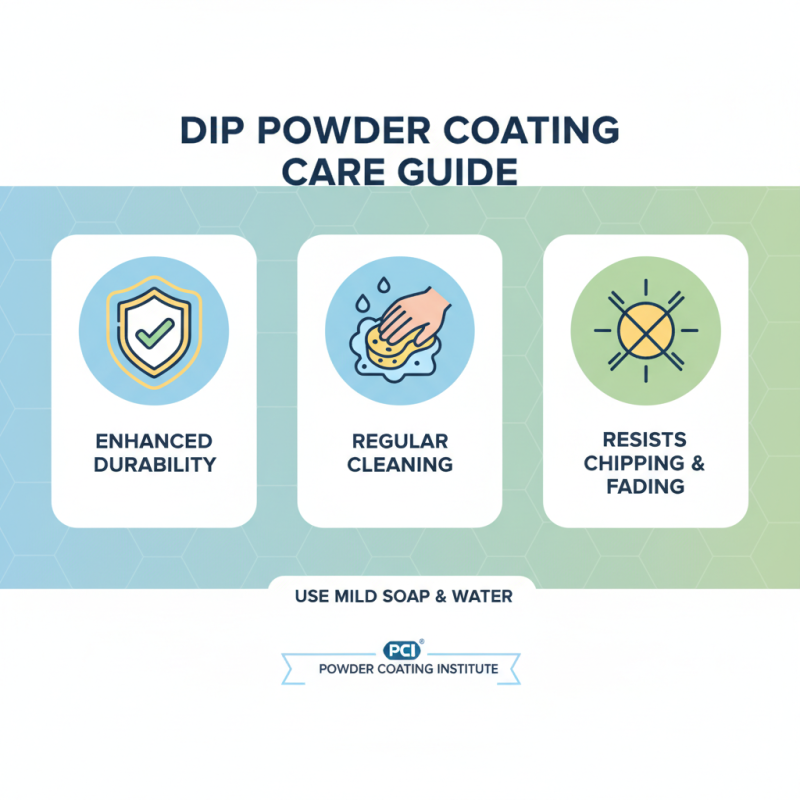

Maintaining dip powder coated surfaces is crucial for preserving their aesthetic appeal and enhancing their longevity. According to the Powder Coating Institute, powder coating can outperform traditional paint in durability, providing superior resistance against chipping, scratching, and fading. However, even the most robust finishes require proper care. Regular cleaning with a mild soap solution can prevent the buildup of dirt and grime, which not only keeps the surfaces looking fresh but also helps to maintain their protective qualities.

In terms of care specifics, it is recommended to avoid harsh chemicals or abrasive materials that can damage the coating. A report from the Technical Association of the Pulp and Paper Industry suggests that using non-abrasive sponges during cleaning will help in preventing scratches on the surface. Additionally, periodic inspections should be conducted to identify any wear or damage early on, enabling timely touch-ups to maintain the integrity of the coating. By implementing these maintenance practices, the lifespan of dip powder coated surfaces can be significantly extended, ensuring the surfaces remain functional and visually pleasing for years to come.