Choosing the right powder coating for your project is crucial. The powder coating industry has seen significant growth. In 2021, it was valued at approximately $12 billion. By 2028, forecasts predict growth to over $20 billion. This surge reflects the increasing demand for durable finishes in various sectors.

When selecting powder coating, consider several factors. Color options and texture vary greatly amongst brands. Some coatings offer superior UV resistance, while others focus on high-temperature tolerance. Each project has unique requirements. It’s essential to match these needs with the right coating system. Yet, many overlook critical details, leading to suboptimal results.

The failure to understand specific properties often leads to undesired finishes. Improper application can also yield unsatisfactory durability. Engaging with suppliers for guidance can mitigate these pitfalls. Educating yourself on powder coating characteristics enhances your project's success. Embracing these complexities helps ensure a lasting, high-quality finish.

Powder coating is a popular finish used on various surfaces. It provides a durable and attractive look. This process involves applying a dry powder which is then cured under heat. The result is a tough, resistant coating that protects against scratches and fading.

Understanding powder coating is essential for making informed choices. The benefits include excellent adhesion, flexibility, and resistance to chemicals. Many people choose powder coating for both aesthetic and practical reasons. It reduces the chances of corrosion and wear, extending the life of the surface.

Tips: Consider the environment of the item you are coating. For outdoor items, choose a formulation with UV protection. Also, think about color and texture, as these can significantly influence the final appearance. The application method can also affect the outcome. Ensure the surface is clean and properly prepped for the best results.

Although powder coating is beneficial, it requires careful selection and preparation. You may face challenges, such as uneven surface texture or color match issues. Be prepared to adjust your approach if things don't go as planned. Taking the time to understand these factors can lead to a successful coating outcome.

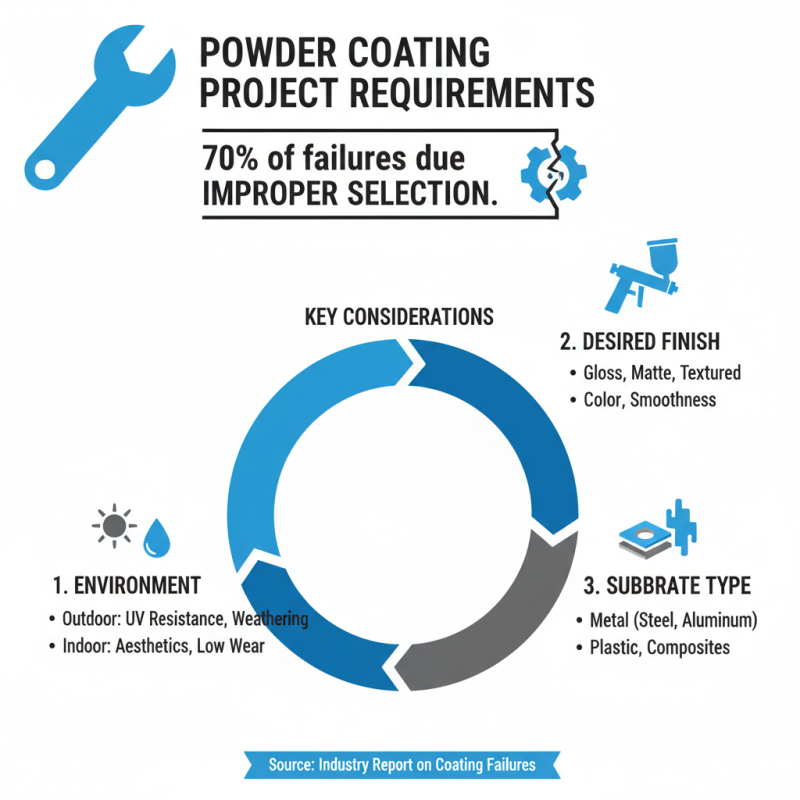

When it comes to powder coating, identifying your project’s specific requirements is crucial. Different projects demand distinct solutions. According to a recent industry report, 70% of coating failures are linked to improper selection of coatings. This highlights the importance of understanding your environment and the desired finish. For example, outdoor applications require coatings with UV resistance, while indoor uses may prioritize aesthetics over durability.

Consider the substrate material as well. Metals, plastics, and wood each require different approaches. A survey by the Coating Institute found that 60% of manufacturers did not account for substrate compatibility. This oversight can lead to poor adhesion, chipping, and costly rework. Additionally, consider the expected wear and tear. Projects exposed to heavy abrasion, like industrial equipment, need tougher coatings.

Colors and textures also cannot be overlooked. Custom colors may not only increase initial costs but also complicate the supply chain. It’s worth noting that some finishes can take longer to cure, impacting your timeline. The balance of aesthetics and functionality requires careful thought. Each choice brings potential drawbacks. Always reflect on these factors to avoid project pitfalls and achieve the best outcome.

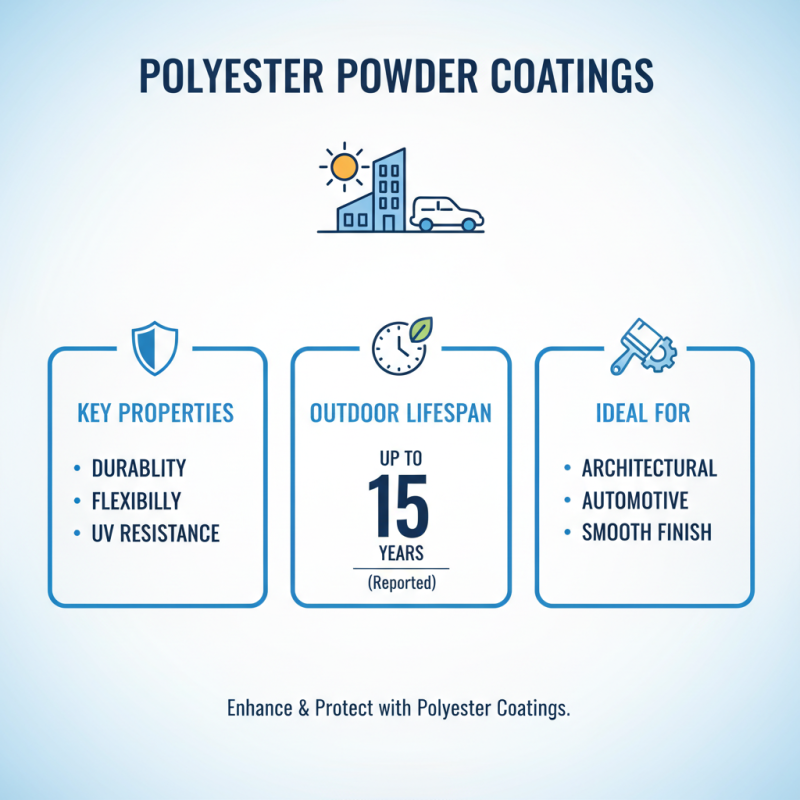

When evaluating different types of powder coatings, consider their unique properties and applications. Polyester powders are common due to their excellent durability, flexibility, and resistance to UV light. Reports indicate they can last up to 15 years outdoors. These coatings are ideal for architectural and automotive finishes. They offer a smooth, attractive finish that can enhance aesthetic appeal.

Epoxy powders, on the other hand, excel in chemical resistance and hardness. They are often used for industrial applications. However, their outdoor performance is limited. Exposure to UV light can lead to color fading and chalking. A balance is needed between looks and longevity when choosing epoxies.

For high-temperature applications, specialty powders like silicone and polyurethane are available. These can withstand extreme conditions. But they may not be suitable for all environments. It’s important to assess the specific needs of your project. Sometimes, the perfect powder coating is an elusive choice that requires comprehensive research and testing. A deep understanding of each powder's pros and cons is essential for success.

When selecting powder coating colors, think about the project’s purpose. Are you aiming for durability or aesthetics? Colors can greatly affect the overall appeal and functionality of your work. Consider the environment where the finished product will be used. For instance, bright colors may look stunning indoors, but they can fade quickly outdoors. The sun’s rays and weather can impact color longevity.

Another essential factor is how the colors interact with each other. Using contrasting hues can enhance visibility and detail. However, choosing too many colors may lead to visual clutter. It’s a fine balance to strike. Analyze your target audience as well. Their preferences should guide your choices. Engaging potential users can provide valuable insights.

It's easy to overlook how different finishes can alter the perception of color. Matte, glossy, or textured surfaces impact how colors look and feel. Be prepared to experiment and adjust. Sometimes, what seems appealing on screen may not translate well to the physical product. Test samples before making a final decision. Reflecting on feedback can help refine your choices.

When selecting a powder coating for your project, testing and application techniques are vital for optimal results. A recent study by the Powder Coating Institute indicates that proper surface preparation can enhance adhesion by up to 30%. This is essential for achieving a smooth finish and long-lasting durability. A clean, dry surface allows the coating to bond effectively.

Tips: Always conduct a small adhesion test before full application. This will ensure the coating holds up under different conditions. Use quality pre-treatment solutions; they significantly improve the final appearance. Apply powder in a controlled environment, avoiding humidity to prevent defects.

Application techniques matter considerably. For instance, maintaining the appropriate distance between the spray gun and the surface can reduce over-spray and uneven coverage. Some professionals recommend a spray distance of about 12-16 inches. This distance can minimize waste and improve the overall finish quality.

Tips: Utilize proper scaffolding or equipment to maintain a consistent spray angle. A consistent angle helps avoid holidays or thin spots. Finally, practice on scrap materials to refine your technique before final application. Perfecting these skills will boost your project's outcome.

This chart represents the popularity of different types of powder coatings used in various projects, indicating their respective application rates.