When considering finishes for your project, powder coating stands out as a versatile option. Expert John Smith, a leader in the powder coating industry, states, "Powder coating offers durability and aesthetic quality that can transform any item." This method is not just about color; it provides a protective layer that enhances the longevity of the product.

The advantages of powder coating are significant. It is more environmentally friendly compared to traditional paint. The process reduces harmful emissions and minimizes waste. However, it is essential to note that not every surface is compatible with powder coating. Some may require specific pre-treatment to achieve optimal results. It can be frustrating if not done correctly.

In everyday applications, powder coating shines. From automotive parts to household items, the finish is smooth and resilient. Yet, achieving the perfect finish requires attention to detail and skill. Every project may come with its unique challenges. Understanding these nuances is crucial for a successful outcome. Powder coating can be a game-changer, but it requires thoughtful execution.

Powder coating is a popular choice for various projects due to its impressive durability and longevity. Unlike traditional paint, powder coating forms a tough, protective layer when cured. This process results in a finish that resists scratches, chipping, and fading. Surfaces treated with powder coating can look new for many years, even under harsh conditions. This is especially useful for outdoor furniture and metal fittings, which face the elements daily.

When considering powder coating, think about the type of finish you want. There are many colors and textures available. Do you want a glossy or matte finish? Also, check if the coating is suitable for the materials you are using. A mismatched coating might not adhere well, leading to peeling later on. Always consult professionals for their insights before making a choice.

One tip is to inspect items regularly. Even powder-coated surfaces can wear down over time. Look for signs of damage and address them quickly. Another tip is to clean your items carefully. Use mild detergents instead of harsh chemicals. Keeping the surface clean maintains its shine and strength. Small changes in care can prolong the life of your coating.

Powder coating has gained popularity due to its environmental benefits. Traditional painting often releases volatile organic compounds (VOCs), which pollute the air. These harmful emissions can contribute to health issues and environmental degradation. In contrast, powder coating contains little to no VOCs, reducing the impact on air quality. This makes it a safer choice for workers and the surrounding community.

Another advantage is the reduction of waste. Traditional paint can lead to surplus materials and hazardous waste. Powder coating, however, allows for overspray to be collected and reused. This closed-loop system minimizes waste significantly. Yet, challenges remain. The application equipment can be costly, which may deter some projects. Additionally, not all surfaces are suitable for powder coating, limiting its versatility.

In terms of durability, powder coating stands out. It resists chipping, scratching, and fading better than conventional paint does. However, it requires precise application and curing methods. Missteps in these processes can lead to imperfections. While powder coating has clear ecological advantages, it necessitates careful handling. Understanding these factors is essential to making an informed decision for your project.

Choosing powder coating for your project can be a smart decision. It often presents a more cost-effective solution compared to liquid coating options. Industry reports indicate that powder coating can save up to 15-30% in application costs. This is largely due to reduced material waste. While liquid coatings typically rely on solvents, powder coatings are free from volatile organic compounds (VOCs). This not only lowers costs but also helps in meeting environmental regulations.

Powder coating requires lower energy consumption as well. Studies show it consumes about 15% less energy during the curing process. However, the initial investment can be higher, especially for equipment. It’s essential to weigh these factors based on your project's scale and financing capabilities.

Tips: Consider the longevity of the finish. Powder coatings usually provide a more durable surface. Think about your project's aesthetic requirements. Powder coatings offer a wide range of colors and textures, which can enhance your design. But remember, transitioning from liquid to powder systems may require training for your team. Being adaptable is key to a successful application.

Powder coating has emerged as a popular choice in various industries due to its application versatility. This finishing process is not just for metal. It's used in automotive, aerospace, and even furniture production. For instance, automotive parts coated with powder finish resist chips and scratches better. This element enhances durability and longevity. In the aerospace sector, weight is crucial. Powder coating adds minimal weight while providing robust protection.

Furniture also benefits from powder coating. Chairs and tables enjoy a vibrant finish that’s hard to replicate. The texture is smooth yet durable. However, not all colors respond the same way. Some shades may fade prematurely when exposed to sunlight. This leaves room for critical evaluation of color choices. Additionally, in the appliance industry, powder coating gives a sleek finish. Yet, customers sometimes report uneven surfaces. This inconsistency can be frustrating, urging manufacturers to reassess their processes.

The environmental aspect adds another layer. Powder coating emits fewer volatile organic compounds (VOCs). This significantly lowers the carbon footprint during production. However, not every facility can maintain the necessary conditions for optimal results. Subpar equipment can lead to issues. The versatility of powder coating continues to showcase its strengths across various sectors. But continuous improvement is essential to fully harness its potential.

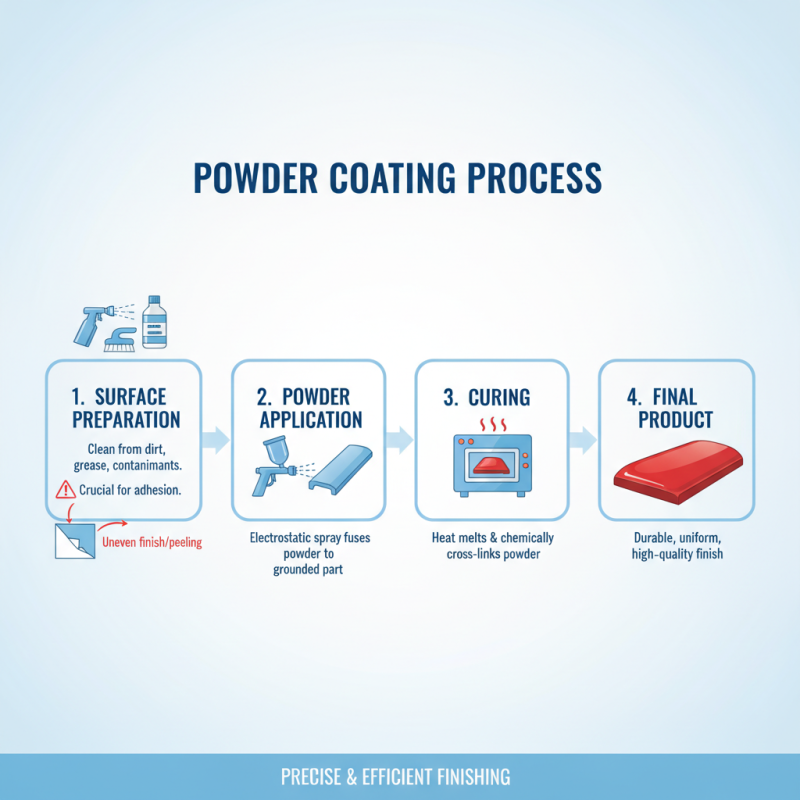

Powder coating is a precise and efficient finishing process. It involves several key steps that contribute to its popularity. First, the surface is prepared. This step ensures that the material is free from dirt, grease, or other contaminants. A clean surface is crucial for the coating's adhesion. Sometimes this part is overlooked, leading to uneven finishes or peeling.

Next, the powder is applied. This is typically done using an electrostatic spray gun. The charged powder particles cling to the surface of the object, which requires a specific application technique. Sometimes, even experienced operators may face challenges here. Over-spraying can occur, leading to waste and a need for touch-ups. Precision is vital, but it's not always easy to achieve.

After application, the coated item is cured in an oven. This heat process melts the powder, forming a durable layer. However, this step must be monitored carefully. Incorrect temperatures can affect the final appearance and strength. Each project presents unique challenges, making the powder coating process both rewarding and complex.