Powder coating is a popular finishing technique for various projects. Its benefits are significant and can enhance both aesthetics and durability. This process uses fine particles of pigment and resin, which are applied as a dry powder. The result is a strong and vibrant finish.

Many industries, from automotive to furniture, utilize powder coating. It is known for its excellent resistance to scratches and chemicals. This makes it ideal for environments that demand durability. However, it is essential to consider some limitations. For instance, not all materials are suitable for powder coating. Some may require special preparation.

Investing in powder coating can lead to long-term advantages. The vibrancy of colors and flexibility in finishes can elevate a project. Despite its many benefits, careful application is crucial. It’s important to avoid oversights in the process. Understanding both strengths and weaknesses can lead to better outcomes in your projects.

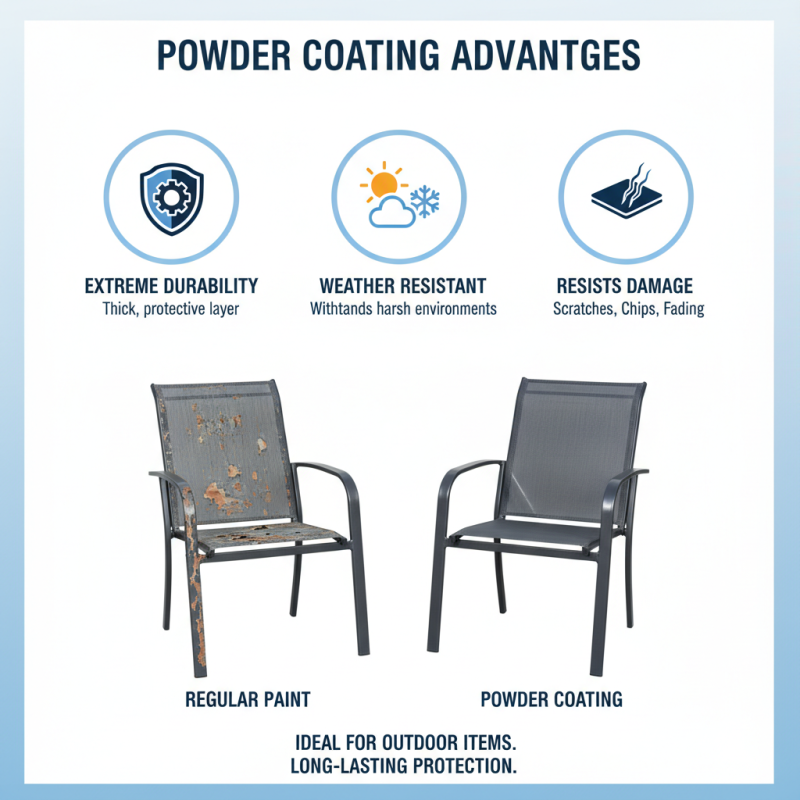

Powder coating offers remarkable durability and longevity for various projects. This process creates a thick, protective layer that withstands harsh environments. Surfaces treated with powder coating can resist scratches, chips, and fading. Imagine metal furniture left outside. Regular paint may peel, but powder coating remains intact. This feature makes it excellent for outdoor items, where exposure to the elements is constant.

Another notable aspect is its resistance to corrosion. Unlike traditional paint, which may weaken over time, powder coating bonds firmly to the surface. This robust adherence ensures that the coating does not flake off easily. Even the best applications sometimes encounter issues, though. Improper surface preparation can lead to chipping. Dust and contaminants can affect adhesion. Such flaws require careful planning and execution, emphasizing the need for skilled application.

Color retention is another benefit. Powder coatings come in a variety of vibrant colors that endure. Over time, they maintain their appearance, resisting discoloration from UV exposure. Yet, some colors may fade more quickly than others, highlighting the importance of selecting the right options. Projects must balance aesthetics with quality for the best results.

Powder coating is becoming increasingly popular due to its cost-effectiveness for various projects. According to a report by the Powder Coating Institute, companies can save up to 20% compared to traditional liquid coatings. This savings stems from reduced material waste. Powder coating processes result in minimal overspray. This efficiency lowers surface prep time and costs.

In addition, powder coating provides durability with lower maintenance expenses over time. A study indicated that parts coated with powder last up to three times longer than those finished with liquid paint. This longevity translates into fewer replacements. Companies can reduce their operational costs significantly by extending the lifespan of coated products.

However, there are challenges. Initial investment costs for equipment may be higher. Not every project is suitable for powder coating due to specific requirements. Some complex shapes may not achieve desired finishes without careful planning. Despite these obstacles, the overall benefits often outweigh the drawbacks. Choosing the right application method is crucial for optimal outcomes.

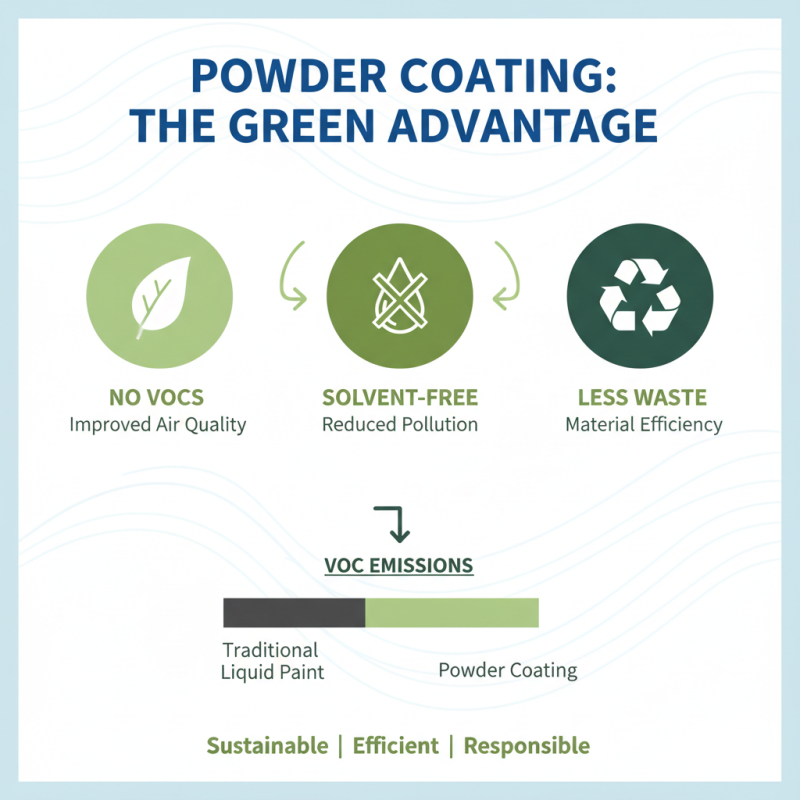

Powder coating offers significant environmental advantages. Unlike traditional liquid paint, powder coating contains no solvents. This means there are fewer volatile organic compounds (VOCs) released into the atmosphere. Studies indicate that reducing VOCs leads to better air quality. Many industries are leaning towards powder coating, recognizing its green benefits.

Moreover, powder coating is efficient and minimizes waste. Excess powder can often be collected and reused. This efficient use of materials not only conserves resources but lowers costs over time. However, some may overlook the intricacies of the application process. Proper equipment and technique are crucial for achieving optimal results.

Another point for reflection is the energy consumption in the curing process. While it is an effective method, businesses should assess their energy sources. Transitioning to renewable energy could amplify the ecological benefits of powder coating. Without such considerations, efforts may fall short of true sustainability.

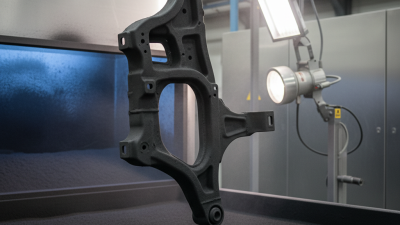

Powder coating is a versatile finishing process used in various industries. It provides a protective layer on metal surfaces, making them durable and visually appealing. From automotive parts to household appliances, the applications are vast.

In the automotive sector, powder coating is crucial for ensuring long-lasting finishes on wheels and frames. It withstands harsh weather conditions, making vehicles more resilient. For office furniture, it offers both aesthetics and durability, allowing for bold colors without compromising quality.

However, not all powder coatings perform equally. Some finishes may fade over time or chip easily under certain conditions. It's essential to choose the right type for your specific project. Reflecting on past experiences can also help refine the selection process. Understanding the variables involved can lead to better outcomes in future applications.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Powder coating provides a tough finish that is more resistant to scratches, chipping, and wear. | Furniture, automotive parts |

| Corrosion Resistance | Offers excellent protection against rust and corrosion, especially for outdoor applications. | Bicycle frames, outdoor furniture |

| Environmentally Friendly | Contains no solvents and releases negligible amounts of VOCs into the atmosphere. | Architectural components |

| Versatility | Available in a wide range of colors, textures, and finishes, catering to various aesthetic preferences. | Decorative items, appliances |

| Cost-effective | Offers a longer-lasting finish, reducing the need for frequent repairs and repainting. | Industrial equipment |

| Fast Application | Quick application process and faster curing times compared to traditional liquid coatings. | Manufacturing processes |

| Enhanced Appearance | Provides a smooth, high-quality finish that enhances the visual appeal of products. | Consumer goods, art pieces |

| Safety | Non-toxic and safe to use, minimizing health hazards during application and disposal. | Food processing equipment |

| Thermal Resistance | Withstands high temperatures without degrading, making it suitable for various industrial uses. | Automotive parts, exhaust systems |

Powder coating offers a wide range of aesthetic benefits for various projects. The most notable feature is the extensive selection of colors and finishes available. You can choose from glossy, matte, or textured finishes, allowing for unique designs. Customers often seek vivid colors to make their products stand out. These choices enhance visual appeal, but the challenge lies in selecting the perfect shade that aligns with project goals.

Additionally, powder coating provides a uniform and durable finish that can elevate the overall look of items. The application process ensures an even layer, preventing drips and uneven textures. However, achieving this consistency requires skilled application. Many overlook the importance of a proper surface preparation, which can affect the final appearance. It’s essential to be mindful of this step to avoid disappointment later.

Color can transform an ordinary project into something extraordinary. Different hues evoke emotions and can influence buyer decisions. When selecting colors, consider the environment where the product will be used. Will it clash with surroundings? Will it fade over time? These are critical considerations that must be addressed. Despite the array of options, making the right choice can feel overwhelming, reflecting the need for thoughtful consideration in every project.