As the DIY culture continues to flourish, the trend of at home powder coating is gaining significant traction in 2025. According to a recent report by the Powder Coating Institute, the at home powder coating market is projected to grow by over 25% this year alone, as more enthusiasts and professionals recognize its unparalleled benefits. This technique not only enhances the aesthetic appeal of various projects but also offers remarkable durability and corrosion resistance compared to traditional paint options.

Expert in the field, Dr. Emily Carter, a leading voice in powder coating technology, emphasizes the transformative potential of at home powder coating. She states, "At home powder coating empowers individuals to achieve professional-grade finishes with ease, enabling a new era of customization for DIY projects." This sentiment resonates deeply with the rising number of hobbyists who seek innovative solutions for home improvement while enjoying the creative process.

With accessible tools and resources readily available, at home powder coating is positioned to become a staple in the toolkit of every DIY enthusiast. The combination of low environmental impact, cost-effectiveness, and the satisfaction of achieving customized results makes this technique an appealing choice for projects ranging from furniture restoration to automotive refinishing. As we delve deeper into the top benefits of at home powder coating, it becomes increasingly clear that this practice is not just a trend but a revolutionary approach to home improvement.

Powder coating has rapidly become a popular choice among DIY enthusiasts and professionals alike, particularly for those seeking to enhance their projects at home. Unlike traditional paint, powder coating uses a dry powder that is electrostatically applied and then cured under heat, resulting in a durable, high-quality finish. According to a report by the Powder Coating Institute, the global powder coating market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. This growth is largely driven by the increasing demand for environmentally friendly and durable coating solutions in various sectors, including automotive, appliances, and furniture.

One of the key advantages of at-home powder coating is the ability for DIYers to achieve a professional finish without the need for expensive equipment typically required by commercial operations. With the right tools, such as a powder spray gun and an oven for curing, individuals can coat items like metal furniture, light fixtures, or even automotive parts with a high degree of control over the finish quality. Furthermore, powder coating is known for its superior resistance to scratches, chips, and fading, making it ideal for projects that require longevity. Research indicates that powder-coated surfaces can be up to three times more resistant to wear and tear compared to traditional liquid coatings, a significant factor for those looking to extend the life of their DIY creations.

Conducting powder coating at home has become an increasingly popular choice for DIY enthusiasts, providing several advantages that enhance both the process and the end result of their projects. One of the key benefits is the cost-effectiveness of setting up a home powder coating system. This allows hobbyists to save money compared to traditional coating methods while enjoying a professional finish. Moreover, the flexibility of home powder coating means that individuals can work on projects at their convenience, free from the constraints of studio schedules or overhead costs associated with professional services.

Another significant advantage of DIY powder coating is the control it offers over the entire process. Home users can select from a wide variety of colors and finishes, allowing them to achieve precisely the desired look for their items. Additionally, the ability to work in a controlled environment reduces the chances of contaminants ruining the finish, which is a common issue in open-air or commercial settings. This control extends to managing the curing process, ensuring optimal results tailored to personal preferences or project requirements. Thus, not only does at-home powder coating streamline project execution but it also empowers individuals to cultivate their creative visions with high-quality outcomes.

| Benefit | Description | Impact on Project |

|---|---|---|

| Cost-Effective | Reduced labor costs by eliminating the need for professional services. | Lower overall project expenses, allowing for budget flexibility. |

| Customization | Endless color and finish options to match personal style. | Unique outcomes that reflect individual creativity. |

| Durability | Powder coating provides a tougher finish than traditional paint. | Projects last longer, reducing the need for frequent refinishing. |

| Eco-Friendly | Powder coating contains no solvents and emits negligible VOCs. | Better for the environment, appealing to eco-conscious DIYers. |

| Ease of Use | User-friendly process suitable for all skill levels. | Encourages more individuals to take on DIY projects. |

When embarking on a DIY powder coating project at home, having the right equipment and materials is crucial for achieving professional results. The fundamental pieces of equipment you will need include a powder coating gun, an oven for curing, and an appropriate powder coating material. A powder coating gun allows for precise application and control of the powder, ensuring an even coat on your project surfaces. Many models are user-friendly and suitable for beginners, making them an excellent investment for DIY enthusiasts.

In addition to the gun, a dedicated curing oven is essential for the finishing process. While some might contemplate using a conventional kitchen oven, it is advisable to use a separate oven as powder coating can produce fumes that may not be suitable for food preparation. For optimal results, selecting an oven that can reach the necessary temperatures (usually between 350°F to 400°F) is critical for curing the powder effectively.

The choice of powder coating materials also plays a significant role in the outcome of your project. Powders come in various colors and finishes, including matte, glossy, and textured options, allowing you to customize your project to your preferences. It’s important to select high-quality powders that are designed for durability and aesthetic appeal. By equipping yourself with the right tools and materials, you can enjoy the benefits of at-home powder coating, transforming ordinary items into stunning, long-lasting pieces with relative ease.

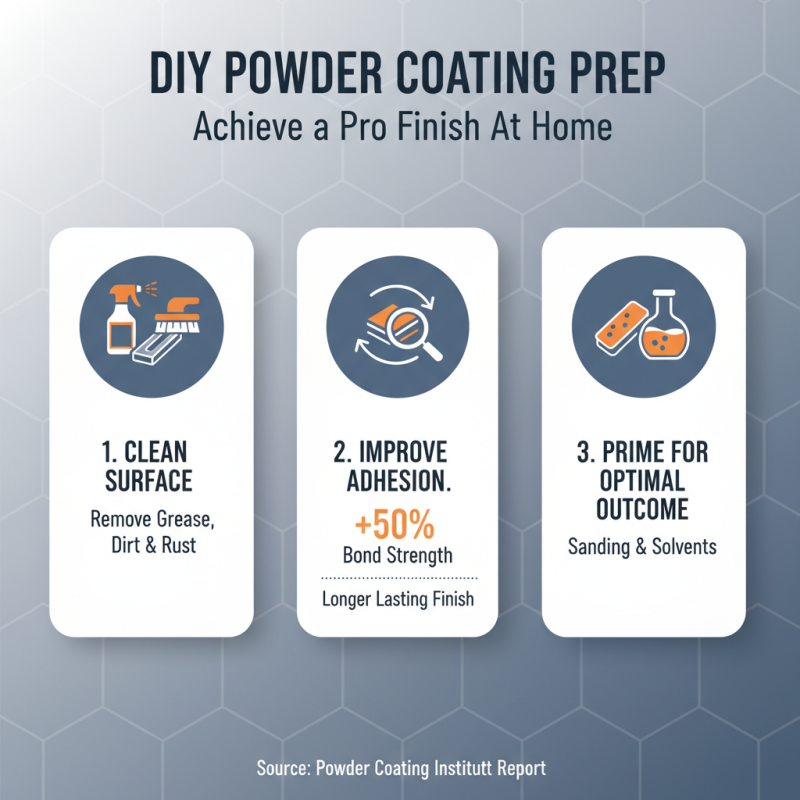

Powder coating at home has gained immense popularity in recent years, especially among DIY enthusiasts looking to achieve a professional finish without the need for expensive equipment. The process begins with proper preparation. It is essential to thoroughly clean the surface of the item you wish to coat, removing any grease, dirt, or rust. According to a report from the Powder Coating Institute, proper surface preparation can improve adhesion by over 50%, significantly extending the life of the finish. This step often involves sanding or using solvents, ensuring the substrate is primed for optimal outcome.

Once the surface is prepared, the next step is to apply the powder coating. This is typically done using a spray gun that electrically charges the powder particles, ensuring they adhere evenly across the surface. The charged particles cling to the object until they are cured in an oven. By 2025, it is projected that around 50% of hobbyists will turn to home powder coating as it allows for customization and control over the color and finish. Curing requires specific temperatures, usually around 350°F, and takes approximately 10-20 minutes depending on the thickness of the coat. The end result is a durable, chip-resistant finish that greatly enhances the lifespan and appearance of various home projects.

When venturing into DIY powder coating at home, safety should always be the top priority. Before starting your project, ensure you are wearing proper personal protective equipment (PPE). This includes a high-quality respirator to protect against inhalation of fine powder particles, gloves to shield your skin, and goggles to prevent irritation from airborne particles. It's vital to work in a well-ventilated area or, ideally, an enclosed space with proper ventilation systems to minimize exposure to harmful fumes and dust.

In addition to personal safety, it's essential to set up a safe workspace. Keep the area free of flammable materials and ensure that you have a fire extinguisher nearby in case of emergency. Properly store your powder coating materials according to manufacturer instructions, and never mix different types of powders without guidance. Regularly inspect your equipment, especially the spray gun and curing oven, to ensure they are functioning correctly and safely. By taking these precautions, you can enjoy the extensive benefits of at-home powder coating while minimizing risks associated with the process.