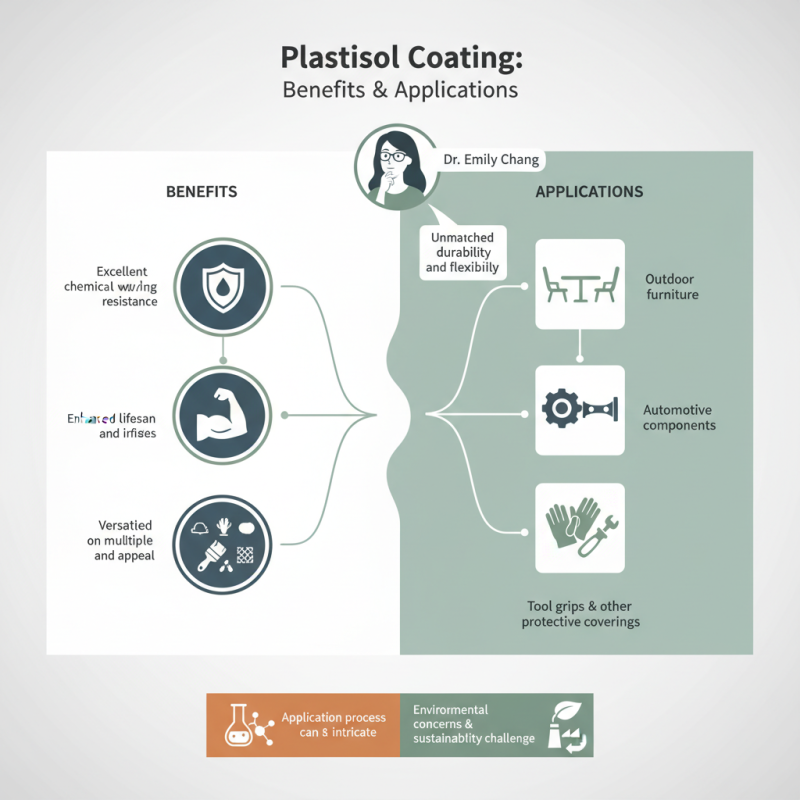

Plastisol coating is gaining traction in various industries for its unique benefits and applications. Renowned expert Dr. Emily Chang, a specialist in industrial coatings, states, “Plastisol coating offers unmatched durability and flexibility.” This material is composed of PVC particles suspended in a liquid plasticizer, making it versatile for numerous uses.

The advantages of plastisol coating are significant. It provides excellent resistance to chemicals and weathering. Many manufacturers are now adopting plastisol for their products due to its exceptional protective qualities. The coating can be applied to metal, wood, and plastic surfaces, enhancing their lifespan and appeal. For instance, it’s commonly utilized in creating outdoor furniture and automotive components.

However, as beneficial as plastisol coating is, there are drawbacks. The application process can be intricate and requires specific conditions for optimal adhesion. Moreover, environmental concerns arise from PVC production. Companies must reflect on these aspects while embracing plastisol's benefits. Balancing innovation with sustainability remains a challenge within the industry.

Plastisol coating is a popular choice in various industries. It is a thick, liquid PVC (polyvinyl chloride) solution. This coating process is simple. The product is heated to form a durable bond when applied to surfaces. Its composition allows it to be flexible yet tough.

One of the key benefits of plastisol is its excellent resistance to chemicals and corrosion. This makes it ideal for outdoor applications where exposure to harsh elements occurs. Additionally, plastisol coatings can be tinted easily to match any color scheme. However, achieving a perfect finish can be challenging. Uneven application may lead to patches or bubbles, which necessitates careful attention during the process.

Plastisol also provides a non-slip surface, enhancing safety in high-traffic areas. Despite its many advantages, it requires proper surface preparation. An overlooked surface may ruin the final result. Understanding these details can help users appreciate the intricacies of plastisol coating. It’s not just a practical choice; it's an art that deserves meticulous execution.

| Dimension | Details |

|---|---|

| Definition | A type of PVC coating used for durability and aesthetics. |

| Composition | Made from polyvinyl chloride (PVC) resin mixed with plasticizers and stabilizers. |

| Benefits | Excellent resistance to chemicals, UV rays, and abrasion. |

| Applications | Used in automotive parts, outdoor furniture, and protective coatings. |

| Thermal Resistance | Can withstand high temperatures without degrading. |

| Color Options | Available in multiple colors for aesthetic purposes. |

| Environment Impact | Can be designed to be more environmentally friendly and recyclable. |

Plastisol coating offers significant advantages across various industries. In automotive manufacturing, it provides excellent corrosion resistance and durability. According to a 2022 industry report, vehicles coated with plastisol have a 40% increase in lifespan compared to those without. This increased durability translates into reduced maintenance costs for vehicle owners.

In the construction sector, plastisol-coated materials are popular for roofing and siding. They help in insulation and weather resistance, creating energy-efficient buildings. A 2023 survey indicated that up to 70% of architects prefer plastisol for its aesthetic appeal and low upkeep needs. Color options are wide-ranging, giving designers creative flexibility while maintaining functionality.

However, the plastisol application process isn't without challenges. Proper surface preparation is crucial for optimal adhesion. In some cases, improper coating thickness can lead to peeling or bubbling. Regular inspections are recommended to ensure long-term performance. These potential drawbacks highlight the need for industry professionals to remain vigilant. Balancing aesthetic desires with practical concerns can be difficult. The effectiveness of plastisol coatings relies heavily on execution during application.

Plastisol coating is increasingly utilized in the automotive and construction sectors. In automotive applications, it provides excellent protection against corrosion. This is especially important given that vehicles are exposed to harsh environments. According to a recent industry report, nearly 70% of vehicles manufactured in 2023 used some form of plastisol coating. This not only extends the lifespan of components but also enhances aesthetic qualities.

In construction, plastisol-coated materials are used extensively. These coatings are applied to roofing, siding, and other exterior elements. They resist UV radiation and harsh weather conditions, making them ideal for various climates. A significant point to consider is that some implementations of plastisol coatings can have environmental impacts. The production process may release VOCs, which raises concerns about air quality. Companies need to focus on improving sustainability while reaping the benefits of plastisol coatings.

Overall, while plastisol coatings offer significant advantages for both automotive and construction sectors, it is crucial to balance their usage with environmental responsibilities. Manufacturers must continue researching eco-friendly alternatives or methods to mitigate any negative impacts associated with traditional plastisol coatings.

Plastisol coating is renowned for its exceptional durability and resistance, making it a popular choice in various industries. One of the primary performance metrics is its exceptional tensile strength. Reports indicate that plastisol coatings can achieve tensile strengths exceeding 2,500 psi. This high tensile strength contributes significantly to its longevity, ensuring the coated products withstand wear and tear.

Moreover, plastisol coatings exhibit remarkable resistance to chemicals and corrosion. According to data from recent industry studies, these coatings can resist a range of corrosive substances, including acids and alkalis. Their ability to maintain integrity under harsh conditions makes them invaluable in sectors like automotive and construction. However, users must be cautious of environmental factors. While plastisol is resistant, prolonged exposure to UV light can cause color fading.

Tips: Regular maintenance is key. Inspect coated surfaces periodically to check for any issues. Early detection can save costs in the long run. Additionally, consider the specific application environment. Understanding the conditions will help in choosing the right thickness and formulation of the plastisol coating.

Plastisol coating technology is evolving rapidly. In 2026 and beyond, we expect several trends to reshape its application. One major trend is the push for eco-friendly formulations. Manufacturers are exploring bio-based materials. This shift aims to reduce environmental impact while maintaining durability.

Moreover, customization is becoming key. Industries are seeking coatings that meet specific needs, such as unique textures and finishes. This level of personalization reflects the demands of modern consumers. It pushes companies to innovate continuously. However, with more options, the risk of inconsistencies increases. Firms need to ensure quality control.

Tips: Consider adopting a lean development approach. This can help balance customization and efficiency. Engage with customers early to understand their preferences. It helps tailor products effectively. Finally, stay informed on regulatory changes. Compliance is crucial for long-term success. As technology advances, so does the need to adapt quickly.